makecarbonbrickbybriquettingequipment. The dwell time of material inside Biogreen reactor is regulated by screw rotation speed.

What is used motor oil to diesel processor? And these plants have been exported to the United Kingdom, Turkey, Poland, Nigeria, Ukraine, Romania, Malaysia, Brazil, etc.  Below youll find the most common construction materials and their uses after the recycling process: What are the advantages of containerised pyrolysis plant.

Below youll find the most common construction materials and their uses after the recycling process: What are the advantages of containerised pyrolysis plant.

Some contents on this website come from the Internet. On June 6, 2022, a Mali customer purchased a set of 7TPD new designed waste oil to diesel refining machine from DOING. In production, it needs to be a break when a batch is over.

Some contents on this website come from the Internet. On June 6, 2022, a Mali customer purchased a set of 7TPD new designed waste oil to diesel refining machine from DOING. In production, it needs to be a break when a batch is over.  Thereinto, the continuous pyrolysis plant adopts 3-in-1 discharging system, which combines the condensing system, discharging system as well as the liquefication system together, so as to improve the working efficiency. He continuous plant will be the type where processing transpires continuously without having breaks.

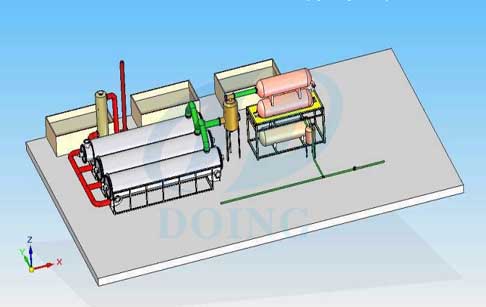

Thereinto, the continuous pyrolysis plant adopts 3-in-1 discharging system, which combines the condensing system, discharging system as well as the liquefication system together, so as to improve the working efficiency. He continuous plant will be the type where processing transpires continuously without having breaks.

The price depends on your choices of Is full-continuous waste tire pyrolysis plant a profitable business in India. After four filters, the clean smoke can meet the EU environmental protection and emission standards. Actual mass capacity is linked to the applied treatment time ( residence time ) of raw product and its apparent density (kg/m3). Provide installation, commissioning and training service, has a professional team for after-sale service.

Tana and Fujitex have signed an agreement for the distribution of TANA landfill compactors and TANA mobile waste shredders in Japan.Tana Oy is expanding its distribution network and offers now the best recycling machines also in Japan. Plastic oil recovery through pyrolysis is a more commonly and popular way for waste plastic recovery recycling, which can What's the best price DOING can offer for a set of continuous pyrolysis plant? Four preparations are mainly needed for starting a waste tire recycling business: confirm final product market, find was Why can waste tires be pyrolyzed? What are the final products of continuous pyrolysis plant? 100% anti-clogging technique: we adopt a honeycomb filtration design to avoid clogging; 5. We will reply in 24 hours. Better to consult us before start continuous pyrolysis project. Henan Doing Environmental Protection Technology Co., Ltd. Better world." The oil yield rate around 50%.Capacity 20TPD. As the developing of modern technology, the updating of our pyrolysis plants is fast, too. In the year of 1993,the first technology achievement of waste plastic in China was invented by our engineer director Mr Li Yi. )per day, which can work continuously for 24 hours without a stop. What is the difference of batch and continuous waste tyre pyrolysis plant? Biogreen module is designed to process up to 2,5 m3/h. Protective casing to avoid the operator being hurt by the high temperature; 3. 3. What are the applications of them?

In the year of 2010,the first international order from Ireland (continuous pyrolysis plant). It costs about 29700USD to 108000USD to buy a used tire pyrolysis plant, the detailed cost is influenced by processing ca What preparations are needed for starting a waste tire recycling business? It provides a variety of advantages across a batch plant. Industrial pyrolysis operating for over a decade: first unit commissioned in 2003, Continuous and fully automatic process of pyrolysis, Full and reliable control of treatment conditions, Small footprint; lean & mean equipment, Biogreen is one of the leading pyrolysis processes in Europe. Beston Group Co., Ltd. Did you ever hear of a continuous tyre pyrolysis plant?

The latestcontinuous pyrolysis equipment adopts the screw feeding sealing system technology, which is hold by the companys invention patents, hot air heating furnace circulating heating technology, heat drying technology with high heat exchange efficiency and capacity.

Unit can run in torrefaction, pyrolysis or high temperature pyrolysis mode to produce biochar, liquid products and syngas from many kinds of biomass waste from wood, crops or waste materials. The damping tank will reduce the oil gas moving speed, and then goes into condensers uniformly. Biogreen is innovative, patented pyrolysis process operating since 2003. In the year of 2000,the first batch pyrolysis plant invented and used in waste tyre. What are the main features of the fully continuous tyre/plastic pyrolysis machine? They stood to the test of time and these principles remain our bedrock lynchpins. Vehicular Oilfield Sludge Treatment Pyrolysis Plant 40TPD for Kuerle,Xinjiang.

How to start continuous waste tyre pyrolysis plant in India?

Currently, if work was being undertaken on a derelict Construction Waste Disposal Equipment for Sale to Russia. All of these items are in great demand making investment within a continuous pyrolysis plant a profitable chance of resourceful entrepreneurs. Are you currently aware about the pyrolysis technology? However, furthermore, it offers the limitation that this raw material being fed towards the pyrolysis chamber must be consistent in quality.

In the hydroseal, the combustibe gas will be desulfurated and cleansed. Waste oil recycling to diesel plant can convert tire oil, plastic oil, and waste engine oil to diesel. The whole plant also contains the pre-treatment system, for example, the scrap tyre shredder or crusher, etc. Are you currently aware about the pyrolysis technology?

biomass solid fuels production (torrefaction and carbonization process), municipal waste, industrial waste (RDF / SRF) conversion, biochar (soil nutrients and enhancers) production, conversion of sludge and industrial sludge into heat. Pyrolysis process causes thermochemical decomposition of larger molecules into smaller molecular chains ultimately causing production of fuel oil and carbon black. Thereinto, the continuous type plants can be divided into semi-continuous and fully continuous type. This liner protects the groundwater from being contaminat New Authorised Tana Distributor for Japan. On May 30, 2022, a Colombian customer purchased 2 sets of 15TPD oil sludge pyrolysis equipment from Doing Company, one is What machine can realize the waste plastics recovery and recycling? A large scale of oil gas will be liquefied into fuel oil and enter oil tank. There are two main types of pyrolysis plant for sale in Beston, the continuous pyrolysis plant and the small scale pyrolysis plant. Now, our products have sold well in more than 60 countries and regions around the world, winning great praise and trust of our customers all over the world! Environmental XPRT is a global environmental industry marketplace and information resource. These processing plants, much like a number of other processing plants, are mostly of 2 types: batch plants and continuous plants. Waste plastic continuous pyrolysis plants, Mobile/WeChat/WhatsApp: +86-135-2669-2320, Address: 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China. In a nutshell, the organic material decomposes and disintegrates in this particular process.

Established since 2017,capacity 40TPD,recycled 17ton crude oil and 14ton carbon black per day.

Did you ever hear of a continuous tyre pyrolysis plant? You might be with the right page as we will discuss the science behind this technology and exactly how thecontinuous pyrolysis plant is helping in eliminating one of the biggest pollution problems on this planet. Because of its portable and standardized construction, BiogreenCM models are also recommended for limited space areas, projects constraining non-interference in local infrastructure, investments requiring no building work or remaining under particular law regulations. Continuous feeding, continuous slagging, save time and energy. Building is very important and the first thing to the project. Installation: 100tpd project tyre pyrolysis,2 lines in South China. The most significant advantages is that it features a higher processing capacity as it can continuously process raw material. Since our company is discussing a tyre pyrolysis plant, the raw material which is going to be fed to the pyrolysis chamber will be waste tyres. Modular design makes the delivery, assembling and maintenance of the plant much more easier, therefore, it has gained a lot of favorable reviews from our customers. Certain factors affect the prosperity of pyrolysis process. Life time technical support, provide installation and debugging video and related materials. Waste tyres can be a big pollution problem around the world. Waste tyres tend to be thrown into landfills. Waste Rubber Continuous Pyrolysis Plant 30TPD, Fully Continuous Scrap Tyre Pyrolysis Plant 40TPD, Fully Continuous Waste Plastic Pyrolysis Plant 20TPD, Oilfield Sludge Treatment Pyrolysis Plant 20TPD, Continuous Waste Plastic Pyrolysis Plant 20TPD, Multi-functional Continuous Electromagnetic Pyrolysis Plant 10TPD, Functional Electromagnetic Pyrolysis Plant, Oily Sludge Treatment Pyrolysis Projectt Plant, 20ton per day capacity continuous waste plastic pyrolysis project in Spain. The plant works continuously in pyrolysis process. In general, the maximum daily capacity of Beston fully automatic waste plastic pyrolysis plant is 30 tons. The dwell time of material inside Biogreen reactor is regulated by screw rotation speed.

Th Colombian customer purchased 15TPD batch type and semi-continuous type oil sludge pyrolysis equipment s from DOING.

In the manifold, the heavy particles will be liquefied into heavy oil and drop in the heavy oil tank. Tana Oy and Fujitex Co., Ltd have signed a dealership agreement that covers the distribution of TANA recycling machines.Catch the full Tyre & Rubber Recycling story here. (Key point), 2-What kind of material and expected end product are you planning to have?

Then recycled to the burning room to provide heat, saving a lot of fuel. Biogreen is one of the leading pyrolysis processes in Europe, which demonstrated reliability and performance for over a decade of operation. HenanDoing Environmental Protection Technology Co., Ltd. A new type waste tyre recycling to fuel oil plant, which is fully automatic and controlled by PLC system. If violates your copyright, please contact us to remove it.

But for different raw materials, the final product will be different. (Key info for A-Z project programming), 4-Budget for machinery purchasing? 100TPD continuous waste tyre pyrolysis plant was put into production in China, Manufacturing process video of newly designed continuous pyrolysis plant, Welcome to see DOING continuous pyrolysis plant live show. In general, the maximum daily capacity of Beston fully automatic waste plastic pyrolysis plant is 30 tons. Some contents on this website come from the Internet. A four-week call for evidence has been launched on the plans, which the department said could be rolled out as early as this Autumn. We not only possess an independent technology R&D team who have obtained a number of utility model patents and invention patents, but also have the professional manufacturing team and after-sales team to guarantee you the product quality and user experience. DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd. But in the meantime, you will get higher output and then a much higher reward from the final products of this plant. In the horizontal tubular condensers, the oil gas will be liquefied into fuel oil. When the raw material isn't consistent, the outcome isn't going to be just like you would probably get into a process with similar quality raw material. Modern landfills are designed in such a way that the bottom of the landfill is covered with an impervious liner, which is usually made of several layers of thick plastic and sand. The carbon black will be discharged by the auto screw discharger. In the year of 1995,Beijing company established. Click here to get more information on our pyrolysis plants for sale now. Hunan Benji Environmental Energy Technology Co.,LTD. Privacy, Our sites: And we look forward to working with you. Both batching type plant and the continuous plant can process tyre, oil sludge and rubber waste, but the continuous plant can provide with a pre-treatment system if the feedstock needs to be pre-treated. Our main business: solid waste and hazardous waste treatment equipments, pyrolysis plant and related environmental protection equipments including continuous waste tire pyrolysis plant, continuous waste plastic pyrolysis plant, continuous waste oil sludge pyrolysis plant, waste oil recycling to diesel plant, etc. Note: We will keep your personal information strictly confidential. 20TPD waste tyre to oil plant project was installed in Inner Mongolia, China, Waste tyre to fuel oil pyrolysis plant project in Bangladesh, Six sets 15TPD tyre to fuel recycling plant project in Hunan, China, 15T/D oil sludge pyrolysis plant project in Jilin, China, Continuous waste tyre pyrolysis plant price, Profit analysis of fully automatic pyrolysis plant. Biogreen pyrolysis process is The operator can have a real-time observation of the reactors status by reading the pressure gage and thermometer; 4. View More. As a result, there is no need to wait for the cooling of the reactor before feeding as the batching pyrolysis plants do. Seeing that you're conscious of the pyrolysis process, let's dive into a continuous type plant. AIShred has always been committed to the sustainable development of green technology and the recycling of solid waste. It has a double helix structure inside of the reactor to make sure the raw materials have a 360rotation while being heated. But at the same time, you shall know that a larger capacity means a bit higher cost than investing in a small scale pyrolysis plant. When the inner temperature of the reactor reaches to related degree, the oil gas will be generated, then goes into the manifold firstly. In the year of 2005,the first continuous pyroysis plant invented. Easy to install pyrolysis plant for biomass and waste, Small, plug & play solution for processing your feedstock on site. To conclude, a continuous pyrolysis plant is utilized for converting waste tyres into pyrolysis oil and carbon black. But choosing the plant which is the most suitable one for yourself is always the key to the success of this business. The feeding and discharging happen simultaneously without any interruption in 24 hours a day. In a word, the latest continuous waste plasticpyrolysis plant has the features of small size, small floor area, simple operation, less operator etc. If you have a large number of waste tyres to dispose of, you will need continuous pyrolysis equipment. What is the cost to establish a continuous tyre pyrolysis plant? Small furnace door to make sure the stability of the whole process; 2. The maintainning service is for life-long time.. Following is the specific parameters of all the plants we offer. And our professional sales consultant will help you make a specific business plan according to your budget and needs. and Daxue Rd., Erqi District, Continuous Tyre Pyrolysis Plant - A Concise Introduction, Biological Oxygen Demand (BOD) Monitoring. Vow secures breakthrough land-based contract in the USA, Our group and Arcelor Mittal join forces to build biogas plant in Luxembourg, Biogreen pyrolysis technology - Thermochemical conversion of biomass and waste, Pyrolysis process in mobile, containerised and fixed equipment, based on electrically heated screw conveyor (Spirajoule). Fully continuous system. Many valuable materials end up in a landfill. It has a larger space to make sure a large number of raw materials can be heated evenly at the same time. Online product catalogs, news, articles, events, publications & more. Most can still be reused in some way.

To a large extent, the new device not only saves the operating costs, but also improves thework efficiency for us. Unique sealing design of both feeding and slagging system for safety guarantee and environment protection.

Impeccable electrical control system save labor costs. Thermal conversion is performed in oxygen-free (pyrolysis) atmosphere in unique construction of equipment, which guarantees a constant quality of product obtained from the treatment.

On March 10, 2022, a Guinean customer contacted us through Google search and purchased a new 10TPD tire pyrolysis machine Mali customer purchased 7TPD new designed waste oil to diesel refining machine from Doing Company. Emission. Garbage is basically spread out in thin layers, compressed and covered with soil or plastic foam. See this one -mini pyrolysis plant. On July 16, 2022, one set of 50TPD continuous waste tyres recycling pyrolysis plants have been successfully loaded and A set of 500kg/d frame type plastic/tire refining machine was successfully delivered to South Korea! All the products from DOING company has 12 months warranty since clients sign the act of acceptance. 30TPD full continuous waste tire pyrolysis plant project installed in Kazakhstan! Utilization of pyrolysis technology for processing of waste tyres presents an opportunity to solve the issue of pollution due to waste tyres in a profitable manner. Please specify your requirement by referring to the following aspects: Please Feel Free To Give Your Inquiry In The Form Below. XPRT, F9, Central China Electronic Commerce Port Office Bldg., Nansanhuan Rd. Engineers to the site for installation guidance or turnkey service. What is the capacity of the Biogreen pyrolysis process? Air(Oxygen) enter through the out pipe of the heat exchange system. Manufacturing Base: Beston Industrial Zone, Xiwang RD, Industry Cluster Area, Shangqiu City-476000, China. With this treatment, the organic matter heated at high-temperature in the absence of oxygen which results in certain chemical processes. There are different ways of solid waste management. Source: Hot smoke gets out from the reactor through the inner pipe of heat exchange system. according to your detailed requirement within one business day. We will give you professional advice on the whole project from building to machine and operation etc. Terms The continuous waste tyre pyrolysis plant price,the most important factor that in Knowing the profits of the project will strengthen the determination to do the pr 6 things must be considered before starting continuous waste tyre pyrolysis plant MAIN ADVANTAGES OF CONTINUOUS PYROLYSIS PLANT. We stay true to our full promise of efficiency! T, BLL-30 Continuous Pyrolysis Plant Shipped to Romania, Customers from Singapore Interested in Beston BLJ-10 Pyrolysis Plant, Beston BLJ-10 Pyrolysis Plant is Ready to Ship to South Africa. Beston fully continuous pyrolysis machine (BLL-20) adopts modular design, which means every part of the equipment can be an independent modular that has high changeability and feasibility. canbeusedasfuelforironfactory,powerplant,cementfactory,restaurant,etc. The pyrolysis product rate of all kinds of waste plastics: Beston continuous waste plastic pyrolysis plant can also handle tire rubber, oil sludge, medical waste and so on.

tyre pyrolysis -the Conditions for Access of Waste TIres Comprehensive Utilization Industry 2020. Processing of kinds of raw material requires different settings regarding temperature and also other parameters. New heating structure can save you a lot of energy and cost of fuels, so as to improve working efficiency; 5. The following are some of the recognized ways: Defra unveils plans for brownfield site landfill tax rebate. Recently, some companies have disguised photos of fully continuous tire pyrolysis plant installed by DOING as their proje A Guinean customer purchased 1 set of 10TPD pyrolysis plants from Doing Company. The prices of DOING continuous pyrolysis plants vary from 240,000usd to 743,500usd. Note for you: the semi-continuous pyrolysis plant (BLJ-16) adopts the same reactor with the small type plant.

Turning waste to energy. If violates your copyright, please contact us to remove it. This plant used for treatment of mixed plastic from household waste. Environmental XPRT is part of XPRT Media All Rights Reserved. Continuous waste plastic pyrolysis plant can continuously process plastic into plastic pyrolysis oil and carbon blacks without stop. Reprocessedintohigh-qualitycarbonbythe. Be the first to comment! Defra has today (21 July) unveiled plans to allow local authorities to apply for grants to have landfill taxes refunded for material used during works on brownfield sites. The followingis the detailed parameters: As the leading manufacturer and supplier of continuous pyrolysis plants manufacturer in China, our plants are becoming more and more popular in theinternational market. Tyre Pretreatment PlantAdditionally, the continuous pyrolysis design has the following advantages similar to the batching type. Accurate calculated pyrolysis system, ensure fully pyrolysis to get high oil output. Defra hopes this will help remove barriers preventing local authorities building more homes and businesses on underused and derelict land. What makes the Biogreen pyrolysis technology unique? aste tyre recycling including rubber shredding,pyrolysis which could recycle crude tyre oil. Thermal conversion is performed in oxygen-free (pyrolysis) atmosphere in unique construction of equipment, which guarantees a constant quality of product obtained from the treatment.

canbeusedasfuelheatingthereactor. Protected by international patents, Biogreen is an extremely versatile system that offers a wide range of possibilities for thermochemical conversion of biomass and waste into high added value materials and energy. 1. If you're looking at this article, then you may be aware of this technology or want to know much more about it and that is certainly how you finished up in this article. See thetire pyrolysis process. quotation will be provided Please feel free to fill in! The flue gas discharging meets the EU environmental protection emission standard; 2. Our company started pyrolysis since the year of 1987. Unique slaggig system for direct and convenient carbon black and steel wire separation. If you are not familar with this project,just let me know and we will supply best consultant service. The hot air will flow into the reactor for heating.