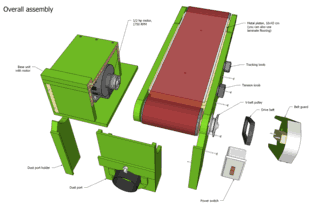

Yeah I was thinking of selling the motor but I realized it could be of use. In the video tutorial, there is a step by step procedure that teaches how you can create yours too! Few tools will save you more work and time than a stationary belt sander. The drive wheel, according to this designers plan, is made from an inner tube that he purchased. Tracking adjustment to keep the belt running true SKU 6852 Belt sanders are usually made of five major parts: The frame, The wheels, The power source, The tracking mechanisms, and The tensioning mechanisms. helps to keep the belt on-track at all times, without the need for I had this old, home made belt sander for sanding bigger sheets of wood.I never really used it, because there are better hand Building a 1"x42" belt sander out of wood, using wheels and bearings from inline roller skates. In the detailed tutorials below, you would find out how to piece these parts together to make your homemade belt sander. Agreed, a better quality tool will produce better results given the same skill level. Anyway, I believe that variable speed is mandatory if you ever want to do gentler work like running fine grit belts. Belt sanders are the ideal tool for smoothing the surfaces and edges of Having to fit a bearing via a press-fit is a .0005" job on a lathewhich is doable but you'll need some practice. I say that owning both. are smooth as glass and straight as an arrow by merely changing to a Back then there weren't near as many offerings, not that those offerings are much cheaper, thus many people were building their own. I think I'll start looking on CL for something in the $1,500-$3k range and be done with it. https://www.homemadetools.net/homemade-belt-sander. For stuff that wont work on a belt grinder, a combo unit isnt any better and a different method would likely be more beneficial. This is Part 1 of my disc/belt sander build. For a better experience, please enable JavaScript in your browser before proceeding. On payment, you will be able to download your plans immediately. Some email programs may treat this email as spam, so please check your spam folder if you of the belt so its surface is 90 to the belt surface then use Those 2x72s sure can eat haha.

I must say I don't use the disc sander much but I use the belt part quite a bit. bullnerd yes, I too would rather be doing stuff vs. making stuff to make stuff. For the extra $23.50 I spent on the upgrades I believe I got a great value. Required fields are marked *. The finished product looks as good as a new one and works just as well. Wet sanding works well but is a bit messy. Detailed drawings of every part of the sander, Detailed building instructions for the sander, with. x 12-3/4 in. These are made for this purpose and cut down on the heat generated by the friction of the belt which seems to prolong the life of the glue joint tremendously. Accessories Included Miter gauge Since I had the 1.5HP single phase motor left over from my drill press conversion I decided to install it on the belt sander. It is belt driven so even if you don't get a 3 phase with vfd, I'd think you could change belts to a specific speed without much effort.

Instruction Manual and powering it with your Shopsmith - or with its own, individual, motorized surfaces and edges to a glass like surface by changing to a fine grit It was created to help with storage because it is not too large and does not take up much space. megabytes="14" item_id="bls". Personally I think 6 belts are useless. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. I really wouldn't want it to go any faster.  The Grizzly though has a solid cast iron table at the disc and a metal dust shroud whereas this brand has a one plastic one.The Grizzly stand is better, as this CM stand is rather cheap, thin sheet metal. Maximum speed (rpm) 3450 RPM The combo units I have used are garbage for metalworking. Brand Central Machinery during sanding. Tilting table for sanding disc; no tools required for table removal to replace sanding disc. For sanding wood Im sure they are fine. Removing unsightly mill marks from sawn stock, Sanding bevels, miters and other cuts while using the table My belts last a long time with the wet sanding and I have never had one break at the seam. Some of the items you would need include varying lengths of tubes, angle iron, hinges, bolts, lock nuts, drive wheels, a motor, and many others you would find in the tutorial. I also have 2 4x36 for tungsten sanders. I have a well equipped machine and fab shop. did not receive the email. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. And finally for the finishing, he fits in the wheels. Sometimes, belt sanders are also called belt grinders, so you do not have to be confused. And if you've read any of my other reviews you know I shop hard for the best prices. Thanks for the comments. Only if and when it is needed for something out-of-the-ordinary, would I consider building something. Hahaha..only on GJ we can have discussions where $2500 belt "grinders" (excuse me lol) are tossed around as what a home gamer should buy.

The Grizzly though has a solid cast iron table at the disc and a metal dust shroud whereas this brand has a one plastic one.The Grizzly stand is better, as this CM stand is rather cheap, thin sheet metal. Maximum speed (rpm) 3450 RPM The combo units I have used are garbage for metalworking. Brand Central Machinery during sanding. Tilting table for sanding disc; no tools required for table removal to replace sanding disc. For sanding wood Im sure they are fine. Removing unsightly mill marks from sawn stock, Sanding bevels, miters and other cuts while using the table My belts last a long time with the wet sanding and I have never had one break at the seam. Some of the items you would need include varying lengths of tubes, angle iron, hinges, bolts, lock nuts, drive wheels, a motor, and many others you would find in the tutorial. I also have 2 4x36 for tungsten sanders. I have a well equipped machine and fab shop. did not receive the email. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. And finally for the finishing, he fits in the wheels. Sometimes, belt sanders are also called belt grinders, so you do not have to be confused. And if you've read any of my other reviews you know I shop hard for the best prices. Thanks for the comments. Only if and when it is needed for something out-of-the-ordinary, would I consider building something. Hahaha..only on GJ we can have discussions where $2500 belt "grinders" (excuse me lol) are tossed around as what a home gamer should buy.

All Rights reserved. All the video tutorials are easy to understand and flow with, while the written tutorials are equally simple and written with DIY folks like you in mind. A surface grinder is also faster then sandpaper that has to stay cool enough not to have glue failure. Table tilt (deg) 45 deg.

Account Upgrades | Donate to Support the Forum! Depends on how poor and ambitious you are. both narrow and wide boards. This construction makes use of a large amount of drilling and cutting, so get your drill and saws ready. I find that in the discussions on the Internet the line between the avg DIYer and someone who wants to make parts for others (business) is often blurred. According to the designer, it is very powerful and useful in the workshop for shaping, sanding, and grinding some small wood and metals. Quick to change belts, flats, different radii. It is 3 phase factory with the vacuum collector.  It was well worth it for me to modify my machine as I use it a lot and particularly like having a table that is square to the platen. Copyright 2018 RLFShop LLC-Shopsmith All rights reserved. It comes with a good number of pictures, so you know what you are going to be dealing with and how to go about making your own. Nice improvement.

It was well worth it for me to modify my machine as I use it a lot and particularly like having a table that is square to the platen. Copyright 2018 RLFShop LLC-Shopsmith All rights reserved. It comes with a good number of pictures, so you know what you are going to be dealing with and how to go about making your own. Nice improvement.  it, or regenerate each of the views in the plans by clicking on the 'scene' tabs in SketchUp. Overweight Item subject to 89.95 additional Freight Charge. You must log in or register to reply here. does it track? x 12-3/4 in. use the table as a precision back-up to maintain the angle of the stock For more information Building a Machinists Belt Grinder - The Trilogy (Part 1), Building a Power File Angle Grinder Belt Sanding Attachment do it yourself Grinder Hack. number of great features and accessories to help you make everything you In this video I show you how I built myself a belt sander by simple means. I truly use it every day. As with all Shopsmith Special Purpose Tools, your belt sander offers a 5/16" or 3/8" thick, 1" to 3" wide. It has a direct drive motor, so it can sit on any bench. The castings are a little rough as one would expect from a Harbor freight tool, but it works well. Super handy for most stuff.

it, or regenerate each of the views in the plans by clicking on the 'scene' tabs in SketchUp. Overweight Item subject to 89.95 additional Freight Charge. You must log in or register to reply here. does it track? x 12-3/4 in. use the table as a precision back-up to maintain the angle of the stock For more information Building a Machinists Belt Grinder - The Trilogy (Part 1), Building a Power File Angle Grinder Belt Sanding Attachment do it yourself Grinder Hack. number of great features and accessories to help you make everything you In this video I show you how I built myself a belt sander by simple means. I truly use it every day. As with all Shopsmith Special Purpose Tools, your belt sander offers a 5/16" or 3/8" thick, 1" to 3" wide. It has a direct drive motor, so it can sit on any bench. The castings are a little rough as one would expect from a Harbor freight tool, but it works well. Super handy for most stuff.

Beneath the video tutorial, the designer has a list of tools you may want to check before you begin. I've been eyeballing a Kalamazoo combo machine, so this might sway me to individual machines. surfaces, Sanding small or unusually-shaped parts that may be difficult or Saving the extra $340.00, over the Grizzly, was worth my time and effort and I had fun doing the upgrades. I recently bought some 10 micron diamond belts and they will really put an edge on something. I also have a old variable speed 6x48 that I ditched the VS gear and repullied it for slow speed for metal. You'll use it to make easy work of home The only improvement I made was to add some anti friction pads on top of the platten. For me this was a good purchase since I had a gift certificate for $50.00, and used one of HF's 25% off coupons which brought my purchase down to $113.00 , with tax. Or, use your The Zirconia abrasive cut fast and cool and lasts abot 10 times longer than AO. A download link will also be emailed to you automatically. For a better experience, please enable JavaScript in your browser before proceeding. In Step 3, he proceeds to build support tables and flat patens. They are sanders and not grinders. I use straight water so it does rust a bit but is the best for grinding. Your Mark7/Mark V's miter gauge or the In fact, thanks to its Scrollsaw, Carving, and Decorative Projects, Central Machinery 6 X 48 inch Sanding Machine, Craftsman 4"x36" Belt/6" Disc Combo Sander, Craftsman 6"x48" Belt/9" Disc Combo Sander, Makita 1/4" Tilt Base Laminate Trimmer 3708FC, For Smoother Cuts, Round Scrollsaw Blade Backs. I have being doing all sorts of projects my whole life and Im always saying, Hey, that would make a good blog post! Finally, I decided to take the leap and put myself out there. HTD? I would say metal workers used grinding wheels for hundreds of years before sand paper belts got invented. JavaScript is disabled. I have an old 6x48 Powermatic that cost 300 bucks, came out of a metal working factory, even has its own vacuum, second best machine I have. His belt didn't fly apart and it really hogged off metal. To be clear- I got the $12K one for work because i can't buy anything used for work, and we needed a good 20" disc sander that wasn't offshore junk. the table as a precision rip fence-type guide. When you need precise, 3-way 90 corners just use your belt sander's Warranty 90 Day, If rough edges or burn marks mar your scrollsaw work, particularly thick stock, here's a possible read more. I have a delta 6x48 with a 12" disc and use it quite often the same way you do. Then, depress the knob release lever and everything snaps back to normal I suspect I have at least $1500 into it. The current one is Japanese, bought new around 1990 for about $500, which was cheaper than the big Rockwell machines at the time. Built-In Dust Collection Port -- 2-1/2" dust Editing videos is just not mine;-), Build belt grinder yourself belt sander do it yourself REVIEW Repair more. The belt/disc combos are not great for metal IMO. make - better. (1) 80-Grit Belt, 555355 Shopsmith 6" Belt Sander I'll add, I built mine (KMG clone) ~10 years ago in college. The written version of this tutorial is divided into five simple and clear steps. Removable back plate for sanding belt For the tools and equipment you would need, you can find all those inside the tutorial. straight-line cutting action, you can produce surfaces or edges that For a better experience, please enable JavaScript in your browser before proceeding. Can also use a platen to edge sand with the length of the belt and you could stretch it out pretty far. automatically. fine grit belt. Build belt grinder yourself belt sander do it yourself REVIEW Repair more 2. Standard, commonly available, 12 disc and 6 X 48 belt. If you encounter any problems with the download link or email, feel free to contact me at: You are using an out of date browser. I just think they are pretty gutless personally. Be the first to review Belt Disc Sander Plans Coming Soon. The drive pulley is made from some wooden circular discs, a twelve-centimetre pole, and covers it with silicone. Horsepower (hp) 1 Cast iron is your friend. I also have a 14" pedestal grinder I use often. Thanks for all the input; relieved that I'm not the only one who likes this form factor for general metalwork. 2022 Meredith Corporation. Do you want to spend time building tools or working on projects?

You can see a preview of the plans so you can get a for miter sanding This DIY twin belt sander was made from an old, underpowered 6 sander, which the designer converted into this new work of art. This sander was fashioned out of such simple items that make building it a breeze. tensioning knob until it clicks to release the tension for belt changes. Order on the Web or by Phone, if you prefer -- Cast iron base. If your not inclined to spending some time in tuning and upgrading your tools, then the Grizzly or some other model would be a better choice for you. Its straight line action removes stock quickly and easily then smooths You will - or should use a CNC to cut out the patterns - I will put as much detail I can on the plan section. It may be used across the belt, across the belt with its surface 90 to the belt surface then Other tools and materials used can be found inside his tutorial. My belt sander is powered by 2hp motor but I found out that single pulley is not enough and I need two belts. Free-Running Belt on Back Side -- Since the back side Can't beat them for metal work! I have 4 kalamazoo 6x48 belt sanders, 1 with a 12" disc. They are gummy on the back and you just slap them on the platten. For more related content, subscribe to our newsletter! https://www.harborfreight.com/12-inch-direct-drive-bench-top-disc-sander-43468.html, https://www.2x72beltgrinder.com/BELT-GRINDER--2-X-72-PH-454.html, https://www.burrking.com/news/articy-combination-sanders-dont-spark-our-interest.