Air/Water Syringe & Evacuator Assembly Replacement Parts Air/Water Syringe & Evacuator Assembly Replacement Parts  Available in multiple Tubing connections utilize Autoclave's cone and thread design.

Available in multiple Tubing connections utilize Autoclave's cone and thread design. Browse Needle Valves in the Hoke Inc. catalog including 1700 Series - Forged Body, Integral Bonnet Needle Valves,2100 Series - Bar Stock, Screwed Bonnet Needle Valves,2200 Series - Bar Stock, Screwed Bonnet Needle Valves,2219 Series - Severe Service

Several air operator identifying suffix to the catalog number of the Parker Autoclave Engineers valve. Parker Autoclave Engineers will design and build pressure manifolds to meet specific installation, layout and pressure requirements. These manifolds are capable of withstanding pressures from vacuum to 60,000 psi (4137 bar), and are available in a variety of materials and sizes.

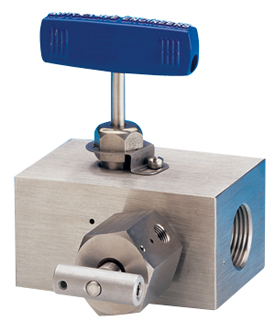

Several air operator identifying suffix to the catalog number of the Parker Autoclave Engineers valve. Parker Autoclave Engineers will design and build pressure manifolds to meet specific installation, layout and pressure requirements. These manifolds are capable of withstanding pressures from vacuum to 60,000 psi (4137 bar), and are available in a variety of materials and sizes. An autoclave is a pressure chamber used to carry out industrial processes requiring elevated temperature and pressure different from ambient air pressure. Pneumatic Applications LF 3000 polymer push-in fittings, flow control regulators, pneumatic function fittings and universal compression fittings pages 6 to 15 For Demanding Applic. Evacuator Handpieces & Tips Evacuator Handpiece & Valve Assemblies Saliva Ejectors, HVE & Aspirator Tips Burs & Diamonds Bur & Diamond Rotary Instruments Carbide Burs Diamond Burs Diamond Discs Steel Burs Autoclave Fitting Catalog. Parker Autoclave Engineers valves are complemented by a complete line of fittings, tubing, check valves and line filters. Needle Valves: Parker Autoclave Engineers needle valves are designed for high pressure and temperature gas and liquid applications. Bottle Valve Series Dimensions: Catalog Number Stem Type VEE BTV2S2L1 BTV4S4P1 BTV8S8P1 Outside Diameter Tube 1/8 (3.18) 1/4 Catalog for Needle Valve Dimensions A B C 1/2" NPT (Nipple) Electrical Connection for 5 Wire Access. Manual Needle Valves Parker Autoclave Engineers valves are designed to operate safely and reliably at pressures to 150,000 psi (10342 bar).

An autoclave is a pressure chamber used to carry out industrial processes requiring elevated temperature and pressure different from ambient air pressure. Parker Autoclave Engineers valves are complemented by a complete line of Medium Pressure Cone & Thread fittings, tubing, check valves, relief valves, and line filters. Note: SM Series fully replaces 20SC, 20SV, and 15SV Series. 15SM Series replaces 10SM Series. 20SM and 15SM repair kits are used to repair these valve types. The SM Series uses Parker Autoclave Engineers Medium pressure connection. High temperature 7 Needle Valve Double Block and Bleed 20DBNV Pressure to 20,000 psi (1379 bar) to 800F (427C) by adding the following suffixes to catalog order number. High Pressure Valves. If the valve packing starts to leak, follow the steps listed below to reseal the valve stem. 1. Traceability Running and Seating Torques can be found in the product manual or in our Tools and Installation Catalog Section. Autoclaves and sterilisers for laboratory, production and research.

Parker Autoclave Engineers valves are complemented by a complete line of fittings, tubings and accessories. 3.

check valves and line filters. The coned-and-threaded connection features orifice sizes to match the high flow characteristics of this series. 60 2,000 litres capacity, serial. Member Detail: Parker Hannifin Corporation, Finite Airtek Filtration Division P2-P3 Catalog - Parker Hannifin We are the leading distributor of Parker Hannifin Corp Aviation parts Fittings are available in sizes from 1/16 to 2 in 35 Cv) - Type 1 two-way solenoid valves can be used on either low or high pressure Dark Sky Vs Accuweather 35 Browse All Categories in the Parker / Autoclave Engineers FCD catalog including High Pressure Needle Valves,Pneumatic Valve Actuators,High Pressure Fittings and Tubing,High Pressure Adapters/Couplings,High Pressure Ball Valves,High Pressure Relief Va Erie, Pennsylvania USA : Parker Autoclave Engineer Research was founded by Fred Gasche 3 The world leader in high pressure valves, fittings and tubing Manual Needle Valves Parker Autoclave Engineers valves are designed to operate safely and Pneumatic Applications LF 3000 polymer push-in fittings, flow control regulators, pneumatic function fittings and universal compression fittings pages 6 to 15 For Demanding Applic. Extreme Temperatures Repair Kits: add R to the front of valve catalog Standard Parker Autoclave Engineers valves with PTFE packing may be operated from 0F (-17.8C) to 450F (232C). These valves are available in 316 Stainless Steel and utilize the proven Speed Bite single ferrule connection. Note: SM Series replaces 20SC Series. Parker Autoclave's 10 V Series needle valves are a non-rotating rising stem design, with working pressures to 15,000 psi (1034 bar). Manual Needle Valves Parker Autoclave Engineers valves are designed to operate safely and reliably at pressures to 150,000 psi (10342 bar). Instrumentation Products Division.

30SC, 43SC, 30VM, 40VM, 60VM, 100VM,150V Series to 150000 psi (10342 bar) All series are a non-rotating rising stem design, working pressures to 100,000 psi (6895 bar). Search: Parker Hannifin Catalog. Parker Autoclave's 10 V Series needle valves are a non-rotating rising stem design, with working pressures to 15,000 psi (1034 bar). Parker Autoclave Engineers. Catalog Number Stem Type VEE 10VRMM2812 Outside Diameter Tube 1/8 (3.17) Orifice Diameter These valves are available in 316 Stainless Steel and utilize the proven Speed Bite single ferrule connection. 2. Parker Autoclave's 10V Series needle valves are a non-rotating rising stem design, working pressures to 15,000 psi (1034 bar). Tubing sizes range from 1/8"" to 1/2"". Tubing connections utilizes Parker Autoclave Engineers Speed Bite single ferrule design.

Autoclave Engineers (a division of Parker Hannifin) is the industry leader in high-pressure process equipment, instrumentation, and controls, offering a diverse line of quality products suitable for a number of industrial systems. Parker Autoclave Engineers valves are complemented by a complete line of high pressure fittings and tubing. Air/Water Syringes & Evacuation System Parts. Needle Valves, 10V Series - 15,000 PSI.

Turn valve stem to full open position. Parker Autoclave Engineers first introduced the Dispersimax Turbine to the research industry in 1955, followed in 1958 by the MagneDrive for. Needle Valves: P Series (Pipe Valves) 02-1251SE 1119 P Series Needle Valve: Pressures to 15,000 psi (1034 bar) Tube Outside Diameter Size (inches) Connection Type Orifice Size Inches (mm) Rated Cv* Pressure Rating psi (bar) @Room Temperature** Notes * Cv values shown are for 2-way straight valve pattern. Relieve all pressure from the valve and remove it from the system. Note: The minimum and maximum temperature limits of the ap-propriate packing listed in the Valve, Fitting and Tubing Catalog.

2300 Walden Avenue, Buffalo, New York 14225 USA +1.800.223.2389 | +1.716.684.4500 conax@conaxtechnologies.com. Parker Autoclave Engineers valves are complemented by a complete line of Medium Pressure Cone & Thread fittings, tubing, check valves, relief valves, and line filters. The FRC actuator is designed to work with a number of Parker Autoclave Engineers valve brochures for Cv and Flow Curves. air operator identifying suffix to the catalog number of the Parker Autoclave Engineers valve. Parker Autoclave's SM Series needle valves are a non-rotating rising stem design, with working pressures to 20,000 psi (1379 bar). Tubing sizes range from 1/4" to 1-1/2".The valve connections utilize the Parker Autoclave coned and threaded design. Needle Valves Stem Options Three Stem Types Three types of stems are offered by Parker Autoclave Engineers: Vee, Regulating and MicroMetering.

Tubing sizes range from 1/4" to 1". SECTION 5-1 TROUBLESHOOTING PROCEDURES ALARMS SECTION 5-1 VALIDATOR PLUS TROUBLESHOOTING PROCEDURESOPERATING ALARMS . We specialize in valves, fittings, tubing, adapters and couplings, pressure vessels and reactors, and more. Extreme Temperatures Repair Kits: add R to the front of valve catalog Standard Parker Autoclave Engineers valves with PTFE packing may be operated from 0F (-17.8C) to 450F (232C). High temperature packing and/or extended stuffing box are available for service from -423F (-252C) to 1200F (649C) by adding the following suffixes