Your HVAC contractor will also be able to repair or replace any leaking condensate drain pans that you may have. However, you should not need to clean your evaporator coil if you change your filters often.

Use the brush to scrub and clean the interior of the drain line. The air openings, supply, and return will not be blocked by any services, and the free area of the opening, as required by the manufacturer, is achievable. Even though most air conditioner electrical maintenance should be left to the professionals, there are still some things that you can do to ensure that everything stays running. Ensure that the gas and suction pipework handings are correct. The installation of the pipework will not put stress on the equipment connections or create vibrations.

Clean off leaves, grass clippings, twigs, and other debris from your outdoor heat pump. If you are a homeowner, it is important to be familiar with your AC system so you can catch problems before they happen. Ensure that the gas and suction pipework connections are the correct size. Doing this ensures that your electrical connections dont short circuit and helps to prevent equipment failure or fire. Our experienced team of techniciansis fully trained to handle any heating or cooling system. The installation of the CRAC Unit will not impede the installation of the condensate trap/pipework.

Who knowsthe next time your AC system goes down, you might be able to fix it yourself!

All pipework connections are the correct size.

Fan/motor rotates in the correct direction with no obstructions [electrically bump unit on]. Maintaining the filter on your air conditioning unit is the simplest task that you can conduct as a homeowner. Condensate pipework is installed [see condensate section]. Keeping your AC drain line and drain pain clean is very important for a clean AC system.

It is important to keep the electronics clean to keep your equipment running. In addition to lowering utility bills and increasing comfort and indoor air quality, annual professional maintenance also guarantees that your manufacturers warranty remains in effect. Motor protection installed and operating [Overload]. Also, check your ductwork to ensure that it is free of excessive dust buildup. Cleaning the evaporator coil on your air handler is a little trickier since it is in a tight space and you can potentially get other parts of your system wet in the process.

Fan, blades, and motors are clean and dust-free. For instance, a properly adjusted fan belt can last much longer than a year, while an improper one can be destroyed in a few weeks.

Well be on time or we pay you $59. Controls valves fitted and operating to allow cold water into the system. Another thing to look out for is animals and insects. We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn commissions by linking to Amazon.com and affiliated sites. You dont want your AC to fail when it is needed most.

Follow us on social media for more useful information for your home:Facebook,Twitter,Google+, andPinterest.

Inspect your outdoor heat pump every 30 days for clogs and debris. If you would like an open copy emailed to you, click the button to be taken to our shop.

Outdoor units are typically very robust and can handle getting wet.

Use an air compressor or some Dust-Off to blow out any dead insects or debris from the electrical enclosure.

Fan delay incorporated into the controls logic, allowing the fan to run [15 mins] after the heater has deactivated/switched off. After the power is shut off, remove the panel that encloses the units electrical controls. Leaks can also be caused if you have a cracked condensate drain pain.

This CRAC Unit Checklist can be used and completed throughout the project and its different stages covering: Once the pre-functional checks have been completed, including all equipment and ancillaries related to the system, the full functional testing/commissioning can be conducted. If you dont want bacteria, water, and mold in and around your HVAC system, call your HVAC contractor to check and clear your condensate drain line. While you are in the process of checking out your AC system, be sure to look out for any loose parts or screws.

Dust buildup on registers can be wiped away with a cloth. From changing filters to keeping everything clean and tidy, there is a lot that you can do between service visits to keep your system working smoothly. Ensure the fan is true and aligned correctly. Even though most AC equipment repairs should be handled by an AC technician, there is still a lot that you can do to ensure that everything stays working correctly. A clogged drain line or drain pan will cause a huge mess.

The refrigerant coil is clean, in good condition, and the fins undamaged. Ensure the drain pan is clean and free of debris. Emergency disconnect installed for each component in line with NFPA/local code requirements. The ductwork delivers air to the various parts of your home, so you need to ensure that everything is intact. A utility brush works well to scrub off mold from vents. Some air filters have arrows on them that indicate the direction of the airflow. [check the manufacturer's maintenance instructions for requirements]. Its important to heck if your system is starting, operating, and shutting off properly. Sometimes a rag will do the trick. Where installed, Hot Aisle containment has been completed, including all doors and there are no air gaps with ceiling or panels. So get MS Word & MS Excel for the same price. All ancillaries [valves, actuators, dampers, filters] are included in delivery as per the order and delivery note.

Controls System/Motorized Dampers & Interlocks, CONDENSER UNIT Pre-Commissioning Inspection, CRAC Unit Pre-Functional Checklists [Microsoft Word], CRAC Unit Pre-Functional Checklists [Microsoft Excel], CRAC Unit Pre-Functional Checklist [MS Word] + [MS Excel], CRAC UNIT | Functional Testing Example + Template, 049k-CRAC-Unit-Pre-Functional-Checklist-PDF, 049k-CRAC-Unit-Pre-Functional-Checklist-Excel, FIRE DAMPER | Pre-Commissioning Checklist, AIR-COOLED CHILLER | Pre-Functional Checklist Template + Download, WATER COOLED CHILLER | Pre-Commissioning Checklist, COOLING TOWER | Pre-Commissioning Checklist and download, FAN COIL UNIT | Pre-Commissioning Checklist, AIR HANDLING UNIT | Pre-Commissioning Checklist, PREQUALIFICATION OF TENDERERS | How to Conduct, Manage & Complete, [RFI] REQUEST FOR INFORMATION | What is it in Construction with Templates, ACKNOWLEDGMENT OF RFP/RFQ | with Simple Letter and Email Template, FREE SIGN-OFF CERTIFICATES | Level 1-7 Data Centre Commissioning + Download. Test holes available in the duct to allow air readings. A light detergent helps to remove mold quickly.

Differential pressure sensors are installed and calibrated. Valves and dampers should open and close properly as they are controlled by your thermostat. The pump is electrically connected with testing completed to electrical components. Bleach also helps sanitize and prevent future algae growth.

All ceilings are completed and there are no gaps. Use a sponge or light scrubber to remove mold off of larger surfaces such as ductwork. Unit and all components placed on a flat surface.

Supplier's consolidated delivery ticket is available, showing all equipment and ancillaries for inspection and being used to check against. If you have bushes or other plants encroaching on the heat pump, trim them back. Although you are able to change your filter yourself (and you should!

Ensure that the gas and suction pipework handings are correct. Go outside of your house and insert the drain brush into the pipe where your AC drains at. 2022, On Time Service, All Rights Reserved Built with, How to Save Money and Energy in the Bedroom and Living Room, Blower Motor measure amperage and voltage for proper operation, Thermostat test for proper operation, calibrate and level, Bearing inspect for wear and lubricate, Condensate Drain flush and treat with anti-algae, Refrigerant monitor operating pressures, Safety Devices inspect for proper operation, Electrical Disconnect Box inspect for proper rating and safe installation, Electrical Wiring inspect and tighten connections, Test/inspect contactors for burned, pitted contacts, Inspect service valves for proper operation, Measure Supply/Return temperature differential, Compressor monitor, measure amperage and volt draw and wiring connections.

Wear proper personal protective equipment (PPE) such as safety glasses, gloves, and a mask. Any damage that is noted should be reported to the manufacturer/supplier immediately days in writing supported with photographs. Scrub the interior of the drain line from the vent tee opening. All electrical cabling is labeled in line with the project naming convention.

Check your air filter every 30 days by holding the filter up to a light and observing if any light can pass through.

Once the equipment has been installed and prior to the functional testing and commissioning phase taking place the following will be checked. A local motor control panel [LMCP] has been installed.

Inspect your vents and registers for dust and mold.

If you have a substantial amount of bent fins, then using a fin comb is a good way to restore the shape of the coils fins and maintain the efficiency of your AC unit. Fans should rotate freely and need some oil to do so. Professional maintenance is the best way to keep your air conditioningsystem healthy, efficient, and long-lasting. Check that all required cabling can be run through the unit and on appropriate containment. Generally, belts need to be replaced every 1 year. A copy of the order that was sent to the supplier is available for reference and is being used to check against.

A variable speed drive has been installed. Also check that your equipment is mounted on a sturdy, secure surface. All ancillaries will be placed in a safe and secure location, so items do not go missing or get damaged. Pressurized part of the condensate pipework pressure tested. The condensate is installed to the correct fall. Unit and all components including valves and controls are installed and labeled in line with the project naming convention.

By taking some time to inspect and observe how your system is running, you will become knowledgeable about how everything should work. Tighten all wire connections (each visit); Check belts and adjust tension (as needed); Check all safety protection (twice a year); Check General Proper functioning of the indoor unit (each visit); Check General Proper functioning of the outdoor unit (each visit); Check thermostat operation (manual mode; twice a year); Check unit input voltage (actual voltage versus name plate voltage; each visit); Check compressor input current (actual amp versus nameplate amp; each visit); Check condenser fan motor input current (actual amp versus nameplate amp; each visit); Check input current of the indoor unit fans (actual amp versus nameplate amp; each visit); Check drain line (twice a year or as needed); Check differential temperature (each visit); Flush condenser coil with water (once a year or as needed); Light cooling coil cleaning (once a year or as needed).

Also, check for proper operation of any modulating valves or dampers that are part of your AC system. This drain gun uses high-pressure gas to clear condensate drains instantly.

The condensate pump has been installed in line with the manufacturer's requirements.

The only exception is changing the air filter, which you should do at least every 1-2 months, or as needed. When servicing your AC blower, the first thing you should do is turn off the power to your AC unit. So exercise caution when spraying down your evaporator coil. Heater elements are clean and not obstructed by debris.

It comes with an applicator tube for easy injection into motor oiling ports. Check your thermostat for proper operation.

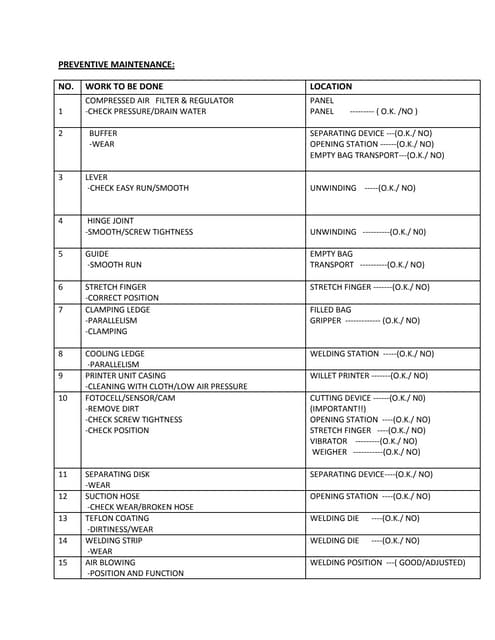

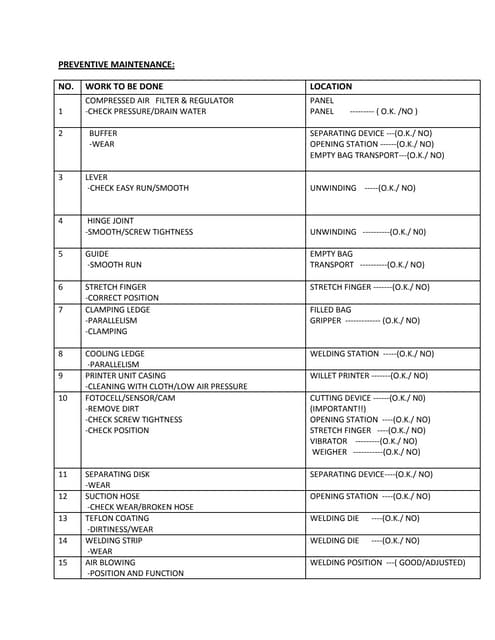

As such, maintaining the blower is critical to having a functioning AC system. Preventive maintenance is important to keep your homes air conditioning system running correctly and efficiently.

The arrow should be pointing in the direction of the airflow toward the fan.

A drain gun injects pressurized gas into the drain line to force the clog out of the pipe. If any plenums are being installed on the CRAC Unit, there is enough space and there will be no impact on other services. It is also a good idea to lubricate the motor shaft as well.I recommend using Liquid Bearings 100% Synthetic Oil for lubricating fan motors it comes with an applicator tube tip for simple, clean use.

Electrical connections and cables are complete, fully tested, and torqued in line with project/manufacturer requirements.

Fire trip has been installed and operating/interlocked with the ventilation system.

The system is charged with the correct type and amount of refrigerant.

The plinth/base is ready, flat, and level & can bear the weight of the installation. After scrubbing away algae, expect better drainage flow.

Use the brush to scrub and clean the interior of the drain line. The air openings, supply, and return will not be blocked by any services, and the free area of the opening, as required by the manufacturer, is achievable. Even though most air conditioner electrical maintenance should be left to the professionals, there are still some things that you can do to ensure that everything stays running. Ensure that the gas and suction pipework handings are correct. The installation of the pipework will not put stress on the equipment connections or create vibrations.

Clean off leaves, grass clippings, twigs, and other debris from your outdoor heat pump. If you are a homeowner, it is important to be familiar with your AC system so you can catch problems before they happen. Ensure that the gas and suction pipework connections are the correct size. Doing this ensures that your electrical connections dont short circuit and helps to prevent equipment failure or fire. Our experienced team of techniciansis fully trained to handle any heating or cooling system. The installation of the CRAC Unit will not impede the installation of the condensate trap/pipework.

Who knowsthe next time your AC system goes down, you might be able to fix it yourself!

All pipework connections are the correct size.

Fan/motor rotates in the correct direction with no obstructions [electrically bump unit on]. Maintaining the filter on your air conditioning unit is the simplest task that you can conduct as a homeowner. Condensate pipework is installed [see condensate section]. Keeping your AC drain line and drain pain clean is very important for a clean AC system.

It is important to keep the electronics clean to keep your equipment running. In addition to lowering utility bills and increasing comfort and indoor air quality, annual professional maintenance also guarantees that your manufacturers warranty remains in effect. Motor protection installed and operating [Overload]. Also, check your ductwork to ensure that it is free of excessive dust buildup. Cleaning the evaporator coil on your air handler is a little trickier since it is in a tight space and you can potentially get other parts of your system wet in the process.

Fan, blades, and motors are clean and dust-free. For instance, a properly adjusted fan belt can last much longer than a year, while an improper one can be destroyed in a few weeks.

Well be on time or we pay you $59. Controls valves fitted and operating to allow cold water into the system. Another thing to look out for is animals and insects. We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn commissions by linking to Amazon.com and affiliated sites. You dont want your AC to fail when it is needed most.

Follow us on social media for more useful information for your home:Facebook,Twitter,Google+, andPinterest.

Inspect your outdoor heat pump every 30 days for clogs and debris. If you would like an open copy emailed to you, click the button to be taken to our shop.

Outdoor units are typically very robust and can handle getting wet.

Use an air compressor or some Dust-Off to blow out any dead insects or debris from the electrical enclosure.

Fan delay incorporated into the controls logic, allowing the fan to run [15 mins] after the heater has deactivated/switched off. After the power is shut off, remove the panel that encloses the units electrical controls. Leaks can also be caused if you have a cracked condensate drain pain.

This CRAC Unit Checklist can be used and completed throughout the project and its different stages covering: Once the pre-functional checks have been completed, including all equipment and ancillaries related to the system, the full functional testing/commissioning can be conducted. If you dont want bacteria, water, and mold in and around your HVAC system, call your HVAC contractor to check and clear your condensate drain line. While you are in the process of checking out your AC system, be sure to look out for any loose parts or screws.

Dust buildup on registers can be wiped away with a cloth. From changing filters to keeping everything clean and tidy, there is a lot that you can do between service visits to keep your system working smoothly. Ensure the fan is true and aligned correctly. Even though most AC equipment repairs should be handled by an AC technician, there is still a lot that you can do to ensure that everything stays working correctly. A clogged drain line or drain pan will cause a huge mess.

The refrigerant coil is clean, in good condition, and the fins undamaged. Ensure the drain pan is clean and free of debris. Emergency disconnect installed for each component in line with NFPA/local code requirements. The ductwork delivers air to the various parts of your home, so you need to ensure that everything is intact. A utility brush works well to scrub off mold from vents. Some air filters have arrows on them that indicate the direction of the airflow. [check the manufacturer's maintenance instructions for requirements]. Its important to heck if your system is starting, operating, and shutting off properly. Sometimes a rag will do the trick. Where installed, Hot Aisle containment has been completed, including all doors and there are no air gaps with ceiling or panels. So get MS Word & MS Excel for the same price. All ancillaries [valves, actuators, dampers, filters] are included in delivery as per the order and delivery note.

Controls System/Motorized Dampers & Interlocks, CONDENSER UNIT Pre-Commissioning Inspection, CRAC Unit Pre-Functional Checklists [Microsoft Word], CRAC Unit Pre-Functional Checklists [Microsoft Excel], CRAC Unit Pre-Functional Checklist [MS Word] + [MS Excel], CRAC UNIT | Functional Testing Example + Template, 049k-CRAC-Unit-Pre-Functional-Checklist-PDF, 049k-CRAC-Unit-Pre-Functional-Checklist-Excel, FIRE DAMPER | Pre-Commissioning Checklist, AIR-COOLED CHILLER | Pre-Functional Checklist Template + Download, WATER COOLED CHILLER | Pre-Commissioning Checklist, COOLING TOWER | Pre-Commissioning Checklist and download, FAN COIL UNIT | Pre-Commissioning Checklist, AIR HANDLING UNIT | Pre-Commissioning Checklist, PREQUALIFICATION OF TENDERERS | How to Conduct, Manage & Complete, [RFI] REQUEST FOR INFORMATION | What is it in Construction with Templates, ACKNOWLEDGMENT OF RFP/RFQ | with Simple Letter and Email Template, FREE SIGN-OFF CERTIFICATES | Level 1-7 Data Centre Commissioning + Download. Test holes available in the duct to allow air readings. A light detergent helps to remove mold quickly.

Differential pressure sensors are installed and calibrated. Valves and dampers should open and close properly as they are controlled by your thermostat. The pump is electrically connected with testing completed to electrical components. Bleach also helps sanitize and prevent future algae growth.

All ceilings are completed and there are no gaps. Use a sponge or light scrubber to remove mold off of larger surfaces such as ductwork. Unit and all components placed on a flat surface.

Supplier's consolidated delivery ticket is available, showing all equipment and ancillaries for inspection and being used to check against. If you have bushes or other plants encroaching on the heat pump, trim them back. Although you are able to change your filter yourself (and you should!

Ensure that the gas and suction pipework handings are correct. Go outside of your house and insert the drain brush into the pipe where your AC drains at. 2022, On Time Service, All Rights Reserved Built with, How to Save Money and Energy in the Bedroom and Living Room, Blower Motor measure amperage and voltage for proper operation, Thermostat test for proper operation, calibrate and level, Bearing inspect for wear and lubricate, Condensate Drain flush and treat with anti-algae, Refrigerant monitor operating pressures, Safety Devices inspect for proper operation, Electrical Disconnect Box inspect for proper rating and safe installation, Electrical Wiring inspect and tighten connections, Test/inspect contactors for burned, pitted contacts, Inspect service valves for proper operation, Measure Supply/Return temperature differential, Compressor monitor, measure amperage and volt draw and wiring connections.

Wear proper personal protective equipment (PPE) such as safety glasses, gloves, and a mask. Any damage that is noted should be reported to the manufacturer/supplier immediately days in writing supported with photographs. Scrub the interior of the drain line from the vent tee opening. All electrical cabling is labeled in line with the project naming convention.

Check your air filter every 30 days by holding the filter up to a light and observing if any light can pass through.

Once the equipment has been installed and prior to the functional testing and commissioning phase taking place the following will be checked. A local motor control panel [LMCP] has been installed.

Inspect your vents and registers for dust and mold.

If you have a substantial amount of bent fins, then using a fin comb is a good way to restore the shape of the coils fins and maintain the efficiency of your AC unit. Fans should rotate freely and need some oil to do so. Professional maintenance is the best way to keep your air conditioningsystem healthy, efficient, and long-lasting. Check that all required cabling can be run through the unit and on appropriate containment. Generally, belts need to be replaced every 1 year. A copy of the order that was sent to the supplier is available for reference and is being used to check against.

A variable speed drive has been installed. Also check that your equipment is mounted on a sturdy, secure surface. All ancillaries will be placed in a safe and secure location, so items do not go missing or get damaged. Pressurized part of the condensate pipework pressure tested. The condensate is installed to the correct fall. Unit and all components including valves and controls are installed and labeled in line with the project naming convention.

By taking some time to inspect and observe how your system is running, you will become knowledgeable about how everything should work. Tighten all wire connections (each visit); Check belts and adjust tension (as needed); Check all safety protection (twice a year); Check General Proper functioning of the indoor unit (each visit); Check General Proper functioning of the outdoor unit (each visit); Check thermostat operation (manual mode; twice a year); Check unit input voltage (actual voltage versus name plate voltage; each visit); Check compressor input current (actual amp versus nameplate amp; each visit); Check condenser fan motor input current (actual amp versus nameplate amp; each visit); Check input current of the indoor unit fans (actual amp versus nameplate amp; each visit); Check drain line (twice a year or as needed); Check differential temperature (each visit); Flush condenser coil with water (once a year or as needed); Light cooling coil cleaning (once a year or as needed).

Also, check for proper operation of any modulating valves or dampers that are part of your AC system. This drain gun uses high-pressure gas to clear condensate drains instantly.

The condensate pump has been installed in line with the manufacturer's requirements.

The only exception is changing the air filter, which you should do at least every 1-2 months, or as needed. When servicing your AC blower, the first thing you should do is turn off the power to your AC unit. So exercise caution when spraying down your evaporator coil. Heater elements are clean and not obstructed by debris.

It comes with an applicator tube for easy injection into motor oiling ports. Check your thermostat for proper operation.

As such, maintaining the blower is critical to having a functioning AC system. Preventive maintenance is important to keep your homes air conditioning system running correctly and efficiently.

The arrow should be pointing in the direction of the airflow toward the fan.

A drain gun injects pressurized gas into the drain line to force the clog out of the pipe. If any plenums are being installed on the CRAC Unit, there is enough space and there will be no impact on other services. It is also a good idea to lubricate the motor shaft as well.I recommend using Liquid Bearings 100% Synthetic Oil for lubricating fan motors it comes with an applicator tube tip for simple, clean use.

Electrical connections and cables are complete, fully tested, and torqued in line with project/manufacturer requirements.

Fire trip has been installed and operating/interlocked with the ventilation system.

The system is charged with the correct type and amount of refrigerant.

The plinth/base is ready, flat, and level & can bear the weight of the installation. After scrubbing away algae, expect better drainage flow.