The continuous cleaning feature incorporated in the Guyson collector ensures efficient operation. Miles Supply exclusively sells the industrys only all-in-one complete sandblasting and abrasive recovery system, featuring advanced servo motor engineering for precise stone engraving.

The continuous cleaning feature incorporated in the Guyson collector ensures efficient operation. Miles Supply exclusively sells the industrys only all-in-one complete sandblasting and abrasive recovery system, featuring advanced servo motor engineering for precise stone engraving.  Office HoursMonday - Friday8:00 AM - 5:00 PM EST, Facebook

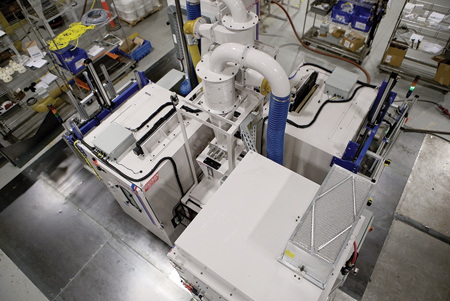

Office HoursMonday - Friday8:00 AM - 5:00 PM EST, Facebook  Shot Blasting & Sandblasting: Whats the Difference? EA0086 SAND HANDLER MC300 9 X 8 X 6, Fraccaroli & Balzan Water Treatment Plants, -Simple computerized or manual operation capabilities, -Abrasive is screened and collected for reuse providing no down time or shoveling sand, -No shutdown time for unplugging clogged nozzles, -Precise control of the blast nozzle for a faster, more uniform cut, -Double walled steel construction frame combined with rubber lined interior walls creating a completely sealed environment, -Provides a cleaner, quieter work environment to help protect employees health, -Excellent visibility and brilliant illumination of the blasting area, -Sandblast booth and sand recovery system are totally self-contained and movable to your location. Stay up to date on exclusive discounts, product news, and catalog previews! Incorporated is a twin spindle feature allows for two part flow.

Shot Blasting & Sandblasting: Whats the Difference? EA0086 SAND HANDLER MC300 9 X 8 X 6, Fraccaroli & Balzan Water Treatment Plants, -Simple computerized or manual operation capabilities, -Abrasive is screened and collected for reuse providing no down time or shoveling sand, -No shutdown time for unplugging clogged nozzles, -Precise control of the blast nozzle for a faster, more uniform cut, -Double walled steel construction frame combined with rubber lined interior walls creating a completely sealed environment, -Provides a cleaner, quieter work environment to help protect employees health, -Excellent visibility and brilliant illumination of the blasting area, -Sandblast booth and sand recovery system are totally self-contained and movable to your location. Stay up to date on exclusive discounts, product news, and catalog previews! Incorporated is a twin spindle feature allows for two part flow.

We work with companies of all sizes from a wide scope of industries to provide surface cleaning, preparing and finishing solutions and many other products and services.

We work with companies of all sizes from a wide scope of industries to provide surface cleaning, preparing and finishing solutions and many other products and services.  The remote-controlled system provides for the adjustment of the speed and path of the nozzle, while a dust collector and media reclaimer capture airborne particles and make it possible to recycle blasted abrasives.

The remote-controlled system provides for the adjustment of the speed and path of the nozzle, while a dust collector and media reclaimer capture airborne particles and make it possible to recycle blasted abrasives.

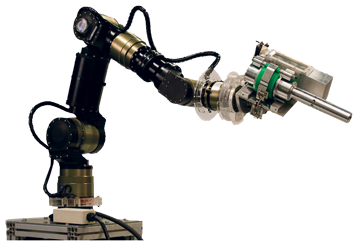

YouTube. The suction of the reclaim system constantly draws all spent and reusable media and the air from the finishing chamber. Robotic blasting is a cutting-edge method of cleaning, stripping, preparing and/or finishing metal surfaces safely, precisely and efficiently. 4 Necessary Precautions for Keeping Sandblasting Safe, Aluminum Oxide: Properties, Uses and Benefits, 70 Willow Springs Circle

YouTube. The suction of the reclaim system constantly draws all spent and reusable media and the air from the finishing chamber. Robotic blasting is a cutting-edge method of cleaning, stripping, preparing and/or finishing metal surfaces safely, precisely and efficiently. 4 Necessary Precautions for Keeping Sandblasting Safe, Aluminum Oxide: Properties, Uses and Benefits, 70 Willow Springs Circle  2022 Guyson Corporation.

2022 Guyson Corporation.

Guyson recognizes the importance of supplying customers with visual indication that are used to balance the reclaim system. Lets take a look at what robotic abrasive blasting is and the benefits it can offer your business. LinkedIn

Guyson recognizes the importance of supplying customers with visual indication that are used to balance the reclaim system. Lets take a look at what robotic abrasive blasting is and the benefits it can offer your business. LinkedIn

All rights reserved. From improved quality results and unmatched reliability to enhanced safety and versatility, there are many reasons to choose robotic abrasive blasting.

All rights reserved. From improved quality results and unmatched reliability to enhanced safety and versatility, there are many reasons to choose robotic abrasive blasting.  When it comes to abrasive blasting for surface preparation and finishing, innovative new technologies are relied on increasingly in the manufacturing process. See SandHandler Info PageFully Automatic Sandblast & Abrasive Recovery System by Miles Supply SandHandler Blogs(SandHandler installation post). EA0022 SAND HANDLER MC400 15 X 8 X 6 The reusable media remains in the system and is recirculated through the gun. In recent years, society has witnessed a rise in the use of robotics that has revolutionized countless industries.

When it comes to abrasive blasting for surface preparation and finishing, innovative new technologies are relied on increasingly in the manufacturing process. See SandHandler Info PageFully Automatic Sandblast & Abrasive Recovery System by Miles Supply SandHandler Blogs(SandHandler installation post). EA0022 SAND HANDLER MC400 15 X 8 X 6 The reusable media remains in the system and is recirculated through the gun. In recent years, society has witnessed a rise in the use of robotics that has revolutionized countless industries.  Also see our SandHandler Front-End curtain.

Also see our SandHandler Front-End curtain.  Tell us what custom size you need or: Learn more about automated blasting systems by contacting us online today.

Tell us what custom size you need or: Learn more about automated blasting systems by contacting us online today.

This precision machine was designed and built for grit blasting of medical implant devices. Terms of Use & Privacy. An automated blasting system removes the operator from the blasting environment, keeping them out of harms way while allowing for continuous operation to maximize uptime and productivity.

This precision machine was designed and built for grit blasting of medical implant devices. Terms of Use & Privacy. An automated blasting system removes the operator from the blasting environment, keeping them out of harms way while allowing for continuous operation to maximize uptime and productivity.  Proper negative pressure is critical when media/dust egress is not allowed.

Proper negative pressure is critical when media/dust egress is not allowed. The Dual Expanded Two-Station RXS-400 System has a small footprint and offers simultaneous dual operation.

If youre looking for a partner for robotic abrasive blasting, were the one-stop shop for everything you require.

If youre looking for a partner for robotic abrasive blasting, were the one-stop shop for everything you require.  Air Blast Equipment & Turnkey Blast Rooms, Outdoor Lighting Pole Blast Finishing and Etching, Hydraulic Fluid Reservoir Blasting and Paint Prep, How to Choose the Right Abrasive for the Job. Our knowledgeable and experienced team will be happy to answer all your questions and provide a free quote based on your project requirements. For reclamation a Model 75/12 Cyclone was used. To balance the reclaim system and ensure negative pressure in the finishing enclosure, continuous cleaning a D-1000 dust collection unit was selected. To understand why this modern method is becoming so popular in manufacturing, automotive, industrial painting and coating and many other industries, consider some of the benefits of automated blasting: At Finishing Systems, we specialize in metal finishing and are experts in the most modern techniques and technologies. Once in the Cyclone body, the reusable media is centrifugally separated from the fractured media and debris, which is removed from the system by the Dust Collector. It aids in noise reduction by surrounding the sliding vertical doors through which the parts enter and exit the blast chamber.

Air Blast Equipment & Turnkey Blast Rooms, Outdoor Lighting Pole Blast Finishing and Etching, Hydraulic Fluid Reservoir Blasting and Paint Prep, How to Choose the Right Abrasive for the Job. Our knowledgeable and experienced team will be happy to answer all your questions and provide a free quote based on your project requirements. For reclamation a Model 75/12 Cyclone was used. To balance the reclaim system and ensure negative pressure in the finishing enclosure, continuous cleaning a D-1000 dust collection unit was selected. To understand why this modern method is becoming so popular in manufacturing, automotive, industrial painting and coating and many other industries, consider some of the benefits of automated blasting: At Finishing Systems, we specialize in metal finishing and are experts in the most modern techniques and technologies. Once in the Cyclone body, the reusable media is centrifugally separated from the fractured media and debris, which is removed from the system by the Dust Collector. It aids in noise reduction by surrounding the sliding vertical doors through which the parts enter and exit the blast chamber.

EA0046 SAND HANDLER MC350 12 X 8 X 6 The front enclosure serves as a device that controls media egress by capturing and returning any dust and residual media back to the machine hopper. York, PA 17406.

EA0046 SAND HANDLER MC350 12 X 8 X 6 The front enclosure serves as a device that controls media egress by capturing and returning any dust and residual media back to the machine hopper. York, PA 17406.