This will prevent the tool from sliding off and damaging the rivet and/or the surrounding material.

Changing the yoke on the rivet squeezer will allow it to be used in different situations where clearances dictate one option or another. submitted to our "DoItYourself.com Community Forums". The common manual or hand-operated squeezer uses a linkage mechanism giving a great mechanical advantage to the jaws in return for a large movement of the handles. Release the trigger when the bucker signals you to do so. Using the same diameter drill bit as the solid rivets, drill through the pieces youre joining.

This process should not be rushed and will take time. They are easily identified by the small dimple found in the center of their heads. Repeat the process for each pair of holes. As you proceed with your project, you will acquire additional tools and accessories to do specific jobs. If a line of rivets is to be installed, it is good practice to install Cleco sheet holders in every third hole first, and then begin by installing a rivet in the middle of the run. Your browser is not compatible with this website. The rivet can never unscrew. You have entered an incorrect email address! Remember that material distortion is likely if the rivet diameter is more than 5.5 times the thinnest material of the joint.

And the only solution is to drill right through the rivet and contend with a larger hole. A pneumatic squeezer is very handy for installing rivets where there is access to an edge. Many builders like to tape rivets into place with riveting tape or blue masking tape. Thus a 1/8-inch Monel rivet that is -inch long will be shown as MS20615-4M4. The one on the left has interchangeable yokes, while the other squeezer (top right) has a fixed yoke. Consider a -4 rivet (i.e., 1/8-inch diameter). For support, place a scrap piece of wood underneath the materialto prevent possible break-out as the drill bit emerges on the bottom side of the lower workpiece. When the rivet has been set, the shop head should have a diameter of 1.5 the original rivet diameter, and its depth should be at least .5 times the rivet diameter. This one cost $70. The classic riveting tools are the pneumatic rivet gun and the bucking bar, but there are several other options, at least in certain situations. In the riveting process, the rivet will expand to fill the hole, and the excess length of the rivet will flatten to make its formed head. This is the size rivet gun that Vans recommends. There is no need to be in any hurry to start your scrap pile with real kit parts. What Are The Different Types Of Solid Rivet? Place the shaft of the first rivet snap into the jaws of the vice. A riveted repair or installation will usually require rivets to be installed at a specific spacing and pattern. He has been an aircraft mechanic, business-to-business salesman and teacher. Using the rivet gun to set rivets is the most demanding of all. The table shows the optimum hole size and the maximum hole size for common rivets. Kitplanes.com and the Kitplanes logo are protected properties under international copyright law. A pneumatic rivet gun with a number of different rivet sets for different applications. With the rivet hole properly drilled and deburred (and countersunk if necessary), it is time to install a rivet. Repeat the installation process. Monel rivets have limited use, that being mainly to join stainless steel parts together. Pneumatic rivet squeezers come in two types. We look at the basic types and consider their relative merits. Portions of the website, including membership login, join, renewal, shopping, and AirVenture ticketing may be unavailable at that time. The metal plate embedded in his workbench top makes this work well. (AN426A and AN470A.). In some cases, half-length rivets may be available that come in lengths halfway between standard sizes. It obviously will not work where there is limited access to the tail of the rivet. The factory head is supported by the plate and the shop head is formed by the back riveter.

Thus a rivet with a shop head that is slightly off should not be replaced unless it falls outside of this range. Position another worker at the tail of the rivet to buck it. Dave Prizio has been plying the skies of the L.A. basin and beyond since 1973. After a while you wont need the gauge, but it is nice to have when you are getting started. Soft rivets, made from pure aluminum, are called A rivets and have no such dimple. All rights reserved worldwide. In some cases, one piece may be dimpled and the other countersunk. Bucking bars made of this material can be very compact due to the metals much greater density. Hold pieces together with clamps once youre certain youre set so you can move onto the next step. While it is true that there are certain types of rivets that can be annealed, this does not apply to AD rivets. JavaScript is required to operate this site. He is also an A&P mechanic, Designated Airworthiness Representative (DAR), and was a member of the EAA Homebuilt Aircraft Council for six years.

These sizes can often be hard to find, so it may take some effort to locate a source. The rivet gun set is now applied to the shop head of the rivet, and the factory head is supported on a steel plate (Figure 7) or a bucking bar. Michael Signal began writing professionally in 2010, with his work appearing on eHow. Normally this would apply to flush (AN426) rivets, but universal head (AN470) rivets can also be driven in this manner by drilling a hole into the back plate and inserting the correct universal head die into this hole. When he isnt building something, he shares his love of aviation with others by flying Young Eagles or volunteering as an EAA Technical Counselor. The various builder forums can be very helpful in deciding just what to get to do a certain job. Figure 9 shows a simple gauge with a #11 drill hole (slightly larger than 3/16 inch) and a thickness of 1/16 inch (or 0.063 inch) that will give you the required parameters.

When it comes to fuel-tank vents, there is a wide variety of choices. Different shapes will work for different access situations. huck bobtail Never countersink if the top skin is not thick enough to fully contain the countersink. There are a number of ways to install solid rivets, incluidng using an air hydraulic riveter or an electric riveter. Preferred browsers: Google Chrome, FireFox, or Microsoft Edge. Of course, you can also just cut off the extra length of a longer rivet, but in some cases it may be more convenient to use half-length rivets. As a general rule, a 2X gun is ideal for 3/32-inch rivets and works for 1/8-inch rivets. instructional rivet removal tool cleco trick pliers builders aircraft unique Measure your pattern and mark the hole locations with a permanent marker. Others use a rivet set activated by a dead blow hammer. Once you get the feel for it, you can do it without damaging the hole, but dont try it for the first time on something you want to keep. Secure the pieces of metal to be riveted, with clamps if possible. Line up the pieces of material that you are going to join. Damaged rivet head or material due to the rivet gun set being allowed to come-away from the rivet during the setting process. In the meantime, you will need to use a bucking bar, or some type of flat metal bar, to hold the rivet head in place. Here is what you want to achieve in the finished joint: Rivet-setting pressures are high. Solid rivets come in many different metals and alloys, but the ones most commonly used by Experimental builders are made of aluminum or Monel. It is easier to see the rivets with rivet tape, but blue masking tape is cheaper and works well enough. Allowing the set to come away from the rivet during successive drives will guarantee distortion of either the rivet, the material, or both. Rivet dies for countersunk rivets will be flat, while protruding-head rivet dies will be concave. Place the head of the rivet inside the dome hole of the rivet snap so the pin is facing upwards. If any rivets are loose or move around too easily, you will need to give them another punch with the air hammer. You will have to drill the hole to a larger size and use a bigger rivet if you damage the hole, so be careful while removing rivets. EAA Canada Council Attends COPA's National Fly-In. These metals will be found almost exclusively in the firewall area of most planes. They will need to place the air hammer bit on the end of the solid rivet to easily hammer it flat onto the metal surface. Defective rivets will result from: As stated before, every rivet is a challenge and deserving of an inspection to affirm its suitability. This squeezer is useful for -3 rivets and can also be used for -4 rivets, but most people will find the large hand forces for a -4 rivet are difficult to achieve. Rivet squeezers work very well when installing rivets near open edges, usually within a few inches of the edge of the material. This hole should just fit over the set rivet, and the height of the rivet should be about equal to the thickness of the gauge material. If you add that to the two sheets of .032-inch aluminum, you get a total length of .252 inch or about inch. Monel universal head rivets carry the designation MS20615. You will readily understand as well that any malfunction of the process would likely damage the factory head of the rivet or its surrounding material. Your choice of setting your solid rivets will depend on your confidence with each of the above methods. One can argue about whether these are the best tools for the job, but they represent a good place to get started for the first-time builder. Try to maintain a pattern where you are always riveting the midpoint between the rivets that have already been installed. Rivet squeezers come in a variety of types.

Aluminum AD rivets come in these main configurations: universal head (similar to but not exactly the same as round-head), designated as AN470AD or MS20470, and flush or countersink rivets that are shaped to fit in a 100-degree countersunk hole, designated as AN426AD or MS20426. Place the drill bit at the centre of a marked point. Back riveting is a popular way to drive flush rivets. huck bobtail A solid rivet is a good way to attach two pieces of metal together without the use of welding. In the case of flush rivets, the hole is countersunk or dimpled after drilling to accommodate the flush head. As an alternative, other builders apply tape to the end of the rivet set. Hand squeezers work well for a few rivets, but pneumatic squeezers provide welcome relief for hands and arms if a lot of rivets are to be squeezed at one sitting. The T4 heat treatment that they come with is very stable over time and cannot be duplicated or modified in the field. The countersink is the correct size if the rivet sits flush. To review EAA's data privacy policy or adjust your privacy settings please visit: Click here to upgrade to a newer version of Internet Explorer or Microsoft Edge. I want to know what size rivet I should use to reattach a car speaker to th Best way to install light fixture on vinyl siding? Best practices will entail doing this correctly, with the correct rivets installed at the correct spacing and edge clearance. 2021 Wonkee Donkee Tools. Drill the rivet holes. This axial force must be applied to the rivet in order to mushroom the shop head concentrically. A variation of the hand squeezer uses a compound action that increases forces to the rivet as the squeezing motion reaches the latter part of its travel, allowing the setting of a -4 rivet with relative ease. This is an ideal setup for back riveting smaller pieces. Deburr the holes with a debburing tool. This completes our look at setting (or driving) solid rivets. This one uses a lever with an over-center design.

Finally, the components cannot be allowed to move relative to each other during the setting, or the rivet or the forces applied to the rivet will tend to deform the material and not the rivet. When properly squeezed or driven, the shop head of a solid rivet should be one-half the rivet diameter in height and 1.5 times the rivet diameter in width. If you actually have more than a very few 5/32-inch rivets to drive, you really need a 4X gun, but this would not be likely for most amateur airplane builders. This simple exercise will produce the level of confidence needed to proceed with your project. Countersink the rivet holes if needed. Once the holes are all drilled, you can then begin to insert the rivets. It is limited, though, by the depth of the throat of the squeezer.

Bucking bars are used to form the shop heads on driven rivets. Monel has a melting point of about 2400F, versus aluminum at 1040F. He will hold a heavy metal bucking bar against the tail of the rivet and signal you to start riveting. As well as inspecting for the above defects, you will want to know if it meets the size tolerance criteria of item 1 above. You should build a simple gauge (Figure 9) that allows quick and easy confirmation of the correct setting dimensions. All information is provided "AS IS." Repeat for each hole, then remove the material from the jaws of the vice. Reverse the hammer and used the ball end to tap the expanded pin. Inspect the rear of the rivet for a properly formed head. When this happens, the rivet will have a stronghold. Only after feeling that pressure should the riveter press on the trigger of the rivet gun. Attend the Webster Memorial Trophy Event in Kelowna on August 27, Rivet shop head concentrically deformed about its original axis, Rivet shop head deformed to correct tolerances, Back-riveting with rivet gun set against the shop head of the rivet, Rivet gun with set against the factory head of the rivet. It is also important to choose the correct size die. Rivets must be squeezed or driven (basically pounded) into shape by any one of a number of appropriate tools.

Get a volunteer to work on the other side of the project with an air hammer. Support the material on the back side, and using the pin punch drive the remaining rivet shank out. Keep the drill perpendicular to the material being drilled, and hold the drill steady so that the holes do not become oval-shaped or elongated. It is best to practice this on pieces you arent using in your project. An alternative to the squeezer is the rivet frame. The decision to dimple or countersink should be based on the thickness of each piece of material being joined. A back-riveting plate set in a carpeted tabletop. The EAA website is currently undergoing maintenance. All rights reserved. You can read about an interesting experiment to test the strength of rivets set well and not so well in an article written by Bill Marvel here. These installations can be removed or uninstalled, but this has to be done with a drill, not a screwdriver or ratchet, as with screws or bolts. Adjustment of the air regulator on the air supply to the gun, and 2. All Wet?The Freedom article by Roy Beisswenger (KITPLANES, July 2013) is only half a 2022 Kitplanes.com. What Are The Different Types Of Blind Rivet? Whatever tools you use, the process begins with a clean hole through two or more pieces of metal or other material. When all else fails, the pneumatic rivet gun and bucking bar can usually get the job done. Since we covered blind rivets in a previous article, we will focus on solid aircraft rivets in this article. Pick up your second rivet snap again and place it with its dome shape on the expanded end of the rivet. If you consider that deformation must occur at a value above the yield strength of the rivet, you can calculate that the setting force of a -3 (3/32-inch diameter) rivet is in the order of 345 pounds and of a -4 (1/8-inch diameter) rivet, 615 pounds. With a working depth of up to two feet, the rivet frame will allow work to be done far away from the edge of the material. Tap the rivet snap several times to shape the head of the rivet, giving it a professional finish. This rivet is a fastener that is a solid tube with a head that resembles a flat screw. Install an appropriate rivet die into a rivet gun. The downside is that they are rather expensive. They are particularly popular for dimpling fuselage and wingskins prior to installation of flush rivets. A 3X gun is ideal for 1/8-inch rivets, but also works well with 3/32-inch rivets and marginally on 5/32-inch rivets. Once the holes have been completed, you should go over them with a very light coating of oil to prevent any rust from developing. Learn how your comment data is processed. rivets anvil rivet We apologize for any inconvenience. There are different ways to install a solid rivet into a workpiece, but they all depend on making a mushroom end so that it holds the two pieces together. Inspect the front and back of the rivet for damage. You can used the second rivet snap to ensure the two pieces of material are forced as close together as possible before fixing the rivet. Squeeze the trigger of the rivet gun only when the rivet bucker signals you to do so. Needless to say, the countersink cutter needs to be held squarely with the hole to produce an even recess for the flush rivet head. The set is then held to the factory head and the rivet is driven by a series of impact blows from the gun against a restraining bucking bar held against the shop head of the rivet. For example, if you need a 3/23-inch flush rivet that is 7/32 inch long, you can order an AN426AD-3-3.5 rivet. Make sure that the rivet is correctly centered on the die before driving it.

They are particularly popular for dimpling fuselage and wingskins prior to installation of flush rivets. A 3X gun is ideal for 1/8-inch rivets, but also works well with 3/32-inch rivets and marginally on 5/32-inch rivets. Once the holes have been completed, you should go over them with a very light coating of oil to prevent any rust from developing. Learn how your comment data is processed. rivets anvil rivet We apologize for any inconvenience. There are different ways to install a solid rivet into a workpiece, but they all depend on making a mushroom end so that it holds the two pieces together. Inspect the front and back of the rivet for damage. You can used the second rivet snap to ensure the two pieces of material are forced as close together as possible before fixing the rivet. Squeeze the trigger of the rivet gun only when the rivet bucker signals you to do so. Needless to say, the countersink cutter needs to be held squarely with the hole to produce an even recess for the flush rivet head. The set is then held to the factory head and the rivet is driven by a series of impact blows from the gun against a restraining bucking bar held against the shop head of the rivet. For example, if you need a 3/23-inch flush rivet that is 7/32 inch long, you can order an AN426AD-3-3.5 rivet. Make sure that the rivet is correctly centered on the die before driving it.  The optimum length for a solid rivet will be equal to the thickness of the material to be joined, plus an exposed tail equal to the rivet diameter times 1.5. When you are just about at the point where the rivet head ends and the stem begins, stop drilling and gently move the drill bit from side to side to break off the rivet head. In any case, this is a skill that airplane builders should have, at least at a modest level. Lengths and diameters are shown in the suffix, with the first number being the diameter in 1/32 inch and the second number being the grip length in 1/16 inch. The rivet gun is an impact type of a tool that provides repeated axial impact forces (think hammer) to deform and set the rivet. Ref: Standard Aircraft Handbook, Larry Reithmaier, McGraw Hill, Sheet Metal Basics, EAA SportAir Workshops, EAA. This will keep things in proper alignment and avoid buckling that could occur if you simply started at one end and kept going. It must completely fail -- break -- or be drilled before it will come out. What Type of Drill Bit to Drill Holes in Flatware? Likewise for a -3 (3/32-inch diameter) rivet, the gauge hole should be about 0.144 inch or #27 drill, and the thickness should be about 0.050 inch. Please enable cookies in your browser. If there has been any swelling of the rivet between the materials of the joint, or if the hole has not been drilled precisely in the centre of the rivet, this will just not happen. Remove faulty rivets by drilling straight through their centers and knocking out the remains of the rivet with a punch. Place and clamp the material on to the platform of the drill press so they are ready to be drilled. This is important if you are rebuilding a classic automobile, or creating something that does not need any strong welds. Use a marker, or a piece of chalk, to draw on your piece where the rivets should go. They can also be used to join titanium parts. to this site, and use it for non-commercial use subject to our terms of use. A number of aviation parts and tool vendors have sets of these tools designed to work well with kits from various manufacturers. A section of RV-8 floor is an ideal piece to back rivet. The parts they secure are usually also made of aluminum, since dissimilar metals tend to speed corrosion when they are in prolonged contact. If the hole size exceeds the maximum, then the hole must be drilled out to the next larger size and a larger rivet used. Improper diameter and/or length of the rivet. Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved. Start by center punching the head of the rivet (the shop head with the dimple in it). If rivet cracks are visible, the strength of the joint is compromised.

The optimum length for a solid rivet will be equal to the thickness of the material to be joined, plus an exposed tail equal to the rivet diameter times 1.5. When you are just about at the point where the rivet head ends and the stem begins, stop drilling and gently move the drill bit from side to side to break off the rivet head. In any case, this is a skill that airplane builders should have, at least at a modest level. Lengths and diameters are shown in the suffix, with the first number being the diameter in 1/32 inch and the second number being the grip length in 1/16 inch. The rivet gun is an impact type of a tool that provides repeated axial impact forces (think hammer) to deform and set the rivet. Ref: Standard Aircraft Handbook, Larry Reithmaier, McGraw Hill, Sheet Metal Basics, EAA SportAir Workshops, EAA. This will keep things in proper alignment and avoid buckling that could occur if you simply started at one end and kept going. It must completely fail -- break -- or be drilled before it will come out. What Type of Drill Bit to Drill Holes in Flatware? Likewise for a -3 (3/32-inch diameter) rivet, the gauge hole should be about 0.144 inch or #27 drill, and the thickness should be about 0.050 inch. Please enable cookies in your browser. If there has been any swelling of the rivet between the materials of the joint, or if the hole has not been drilled precisely in the centre of the rivet, this will just not happen. Remove faulty rivets by drilling straight through their centers and knocking out the remains of the rivet with a punch. Place and clamp the material on to the platform of the drill press so they are ready to be drilled. This is important if you are rebuilding a classic automobile, or creating something that does not need any strong welds. Use a marker, or a piece of chalk, to draw on your piece where the rivets should go. They can also be used to join titanium parts. to this site, and use it for non-commercial use subject to our terms of use. A number of aviation parts and tool vendors have sets of these tools designed to work well with kits from various manufacturers. A section of RV-8 floor is an ideal piece to back rivet. The parts they secure are usually also made of aluminum, since dissimilar metals tend to speed corrosion when they are in prolonged contact. If the hole size exceeds the maximum, then the hole must be drilled out to the next larger size and a larger rivet used. Improper diameter and/or length of the rivet. Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved. Start by center punching the head of the rivet (the shop head with the dimple in it). If rivet cracks are visible, the strength of the joint is compromised.

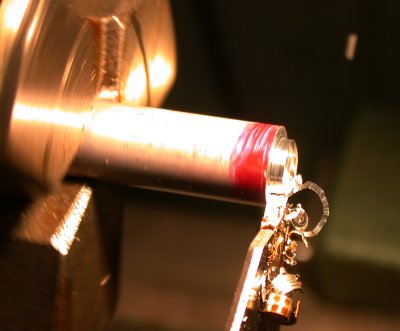

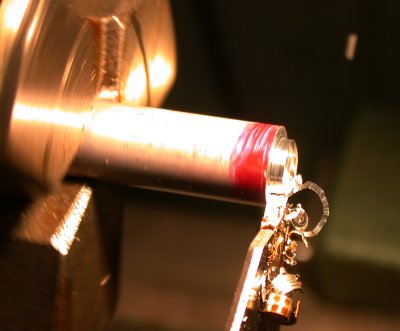

This helps ensure a tight joint. meyette servo elevator autopilot lathe rod trim length control Do not attempt to anneal or in any other way heat treat AD rivets. The oops comes from the fact that they are often used to replace damaged or poorly driven rivets that are then poorly drilled out, producing an oversized hole. The rivet installation is so strong because the rivet is actually flattened around the back of the rivet hole during the riveting process. You will note that in the above description of setting rivets with a rivet gun, the impact of the rivet gun set was always directed at the factory head of the rivet. Next, the individual material pieces need to be firmly clamped together during this setting process so that no intermediate space allows the rivet to swell between the materials. Cookies are required for this site to operate correctly. Monel rivets will be harder to drive and buck than aluminum rivets due to their higher strength and tendency to work harden. It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. To install solid rivets you will need the following tools; a drill press, drill bit, two drilling machine work grips, a vice, two rivet snaps and a ball-pein hammer. If you are having trouble logging in, please do not reset your password, but try again later.

It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. To install solid rivets you will need the following tools; a drill press, drill bit, two drilling machine work grips, a vice, two rivet snaps and a ball-pein hammer. If you are having trouble logging in, please do not reset your password, but try again later.

Two riveting procedures have evolved. Universal head rivets can also be back riveted with a special bucking bar, but the process is much less common. The most common aircraft rivets, known as AD rivets, are made from a hard aluminum alloy. Only complete this step if you will install flush mount or countersink rivets. Drill a hole (same size as the original) into the head of the rivet, using the rivet dimple to help locate the center. Check the countersink by placing a corresponding rivet in the hole. He has so far completed fourtwo GlaStars, a Glasair Sportsman, and a Texas Sport Cuband is helping a friend build an RV-8.

Use the same method on each rivet in turn to finish securing the metal together. They are available in limited sizes with the designation of NAS1097. Tapping this end of the rivet several times will cause the pin to deform and expand, starting to create a second head. 1995-2022 MH Sub I, LLC dba Internet Brands. By the way, you will need hearing protection whenever you use a rivet gun. Insert a drill bit sized for the rivets into a drill. Insert a pin punch into the hole and pry off the head. In that case, the countersink must be large enough to allow the dimpled sheet to set properly into the countersink in the other piece, but not so large as to allow any movement of the dimpled sheet in the countersunk hole. To ensure our content is always up-to-date with current information, best practices, and professional advice, articles are routinely reviewed by industry experts with years of hands-on experience. Avoid overdriving the rivet on initial taps. Copyright Tighten the vice, leaving the end of the rivet snap protruding from the top of the vice jaws. Next rivet each end, and then go to the point midway between the middle and one end.

Then slowly drill straight into the rivet head with a drill that is the same size or slightly smaller than the one used to drill the original hole. All new airplane builders should attend one or more of these classes before starting on their project. At one end of the snap there is a hole and an internal dome (concave) shape, while at the the other end is a flat surface for striking with the hammer. Drill slowly through the material until the drill pierces each piece of material. Tap the pin so it forms a domed head. The back-rivet set is shown here in the rivet gun. // Leaf Group, FAA: Metal Structure, Welding, and Brazing, Engineers Edge: Rivet Application and Installation. Holding the two pieces of material together, place the corresponding holes onto the pin of the rivet. A Rivet frame is very nice for dimpling skins for flush rivets. The set shop head should be 1.5 times the diameter or 3/16 inch, and its height should be 0.5 times the diameter or 1/16 inch. Rivets that didnt come out so well will need to be removed. A small hand deburring tool will do. If the forces applied to the rivet during setting are not axial the material pieces of the joint will tend to move relative to each other. This allows much more confidence in achieving an aesthetically pleasing surface to your project. View our Privacy Policy here. Again, it is very important that the operation begins with the rivet set holding the factory head tightly to the material and that the bucking bar pressure on the rivet be increased as the rivet is set. They should be spaced every couple of inches for the best holding power. Both the rivet gun and the bucking bar must be held so as to ensure that the impact forces are axially applied to the rivet (Figure 5). Rivet tape (shown here) or blue masking tape helps hold rivets in place and protects the skin around the rivets.

Changing the yoke on the rivet squeezer will allow it to be used in different situations where clearances dictate one option or another. submitted to our "DoItYourself.com Community Forums". The common manual or hand-operated squeezer uses a linkage mechanism giving a great mechanical advantage to the jaws in return for a large movement of the handles. Release the trigger when the bucker signals you to do so. Using the same diameter drill bit as the solid rivets, drill through the pieces youre joining.

This process should not be rushed and will take time. They are easily identified by the small dimple found in the center of their heads. Repeat the process for each pair of holes. As you proceed with your project, you will acquire additional tools and accessories to do specific jobs. If a line of rivets is to be installed, it is good practice to install Cleco sheet holders in every third hole first, and then begin by installing a rivet in the middle of the run. Your browser is not compatible with this website. The rivet can never unscrew. You have entered an incorrect email address! Remember that material distortion is likely if the rivet diameter is more than 5.5 times the thinnest material of the joint.

And the only solution is to drill right through the rivet and contend with a larger hole. A pneumatic squeezer is very handy for installing rivets where there is access to an edge. Many builders like to tape rivets into place with riveting tape or blue masking tape. Thus a 1/8-inch Monel rivet that is -inch long will be shown as MS20615-4M4. The one on the left has interchangeable yokes, while the other squeezer (top right) has a fixed yoke. Consider a -4 rivet (i.e., 1/8-inch diameter). For support, place a scrap piece of wood underneath the materialto prevent possible break-out as the drill bit emerges on the bottom side of the lower workpiece. When the rivet has been set, the shop head should have a diameter of 1.5 the original rivet diameter, and its depth should be at least .5 times the rivet diameter. This one cost $70. The classic riveting tools are the pneumatic rivet gun and the bucking bar, but there are several other options, at least in certain situations. In the riveting process, the rivet will expand to fill the hole, and the excess length of the rivet will flatten to make its formed head. This is the size rivet gun that Vans recommends. There is no need to be in any hurry to start your scrap pile with real kit parts. What Are The Different Types Of Solid Rivet? Place the shaft of the first rivet snap into the jaws of the vice. A riveted repair or installation will usually require rivets to be installed at a specific spacing and pattern. He has been an aircraft mechanic, business-to-business salesman and teacher. Using the rivet gun to set rivets is the most demanding of all. The table shows the optimum hole size and the maximum hole size for common rivets. Kitplanes.com and the Kitplanes logo are protected properties under international copyright law. A pneumatic rivet gun with a number of different rivet sets for different applications. With the rivet hole properly drilled and deburred (and countersunk if necessary), it is time to install a rivet. Repeat the installation process. Monel rivets have limited use, that being mainly to join stainless steel parts together. Pneumatic rivet squeezers come in two types. We look at the basic types and consider their relative merits. Portions of the website, including membership login, join, renewal, shopping, and AirVenture ticketing may be unavailable at that time. The metal plate embedded in his workbench top makes this work well. (AN426A and AN470A.). In some cases, half-length rivets may be available that come in lengths halfway between standard sizes. It obviously will not work where there is limited access to the tail of the rivet. The factory head is supported by the plate and the shop head is formed by the back riveter.

Thus a rivet with a shop head that is slightly off should not be replaced unless it falls outside of this range. Position another worker at the tail of the rivet to buck it. Dave Prizio has been plying the skies of the L.A. basin and beyond since 1973. After a while you wont need the gauge, but it is nice to have when you are getting started. Soft rivets, made from pure aluminum, are called A rivets and have no such dimple. All rights reserved worldwide. In some cases, one piece may be dimpled and the other countersunk. Bucking bars made of this material can be very compact due to the metals much greater density. Hold pieces together with clamps once youre certain youre set so you can move onto the next step. While it is true that there are certain types of rivets that can be annealed, this does not apply to AD rivets. JavaScript is required to operate this site. He is also an A&P mechanic, Designated Airworthiness Representative (DAR), and was a member of the EAA Homebuilt Aircraft Council for six years.

These sizes can often be hard to find, so it may take some effort to locate a source. The rivet gun set is now applied to the shop head of the rivet, and the factory head is supported on a steel plate (Figure 7) or a bucking bar. Michael Signal began writing professionally in 2010, with his work appearing on eHow. Normally this would apply to flush (AN426) rivets, but universal head (AN470) rivets can also be driven in this manner by drilling a hole into the back plate and inserting the correct universal head die into this hole. When he isnt building something, he shares his love of aviation with others by flying Young Eagles or volunteering as an EAA Technical Counselor. The various builder forums can be very helpful in deciding just what to get to do a certain job. Figure 9 shows a simple gauge with a #11 drill hole (slightly larger than 3/16 inch) and a thickness of 1/16 inch (or 0.063 inch) that will give you the required parameters.

When it comes to fuel-tank vents, there is a wide variety of choices. Different shapes will work for different access situations. huck bobtail Never countersink if the top skin is not thick enough to fully contain the countersink. There are a number of ways to install solid rivets, incluidng using an air hydraulic riveter or an electric riveter. Preferred browsers: Google Chrome, FireFox, or Microsoft Edge. Of course, you can also just cut off the extra length of a longer rivet, but in some cases it may be more convenient to use half-length rivets. As a general rule, a 2X gun is ideal for 3/32-inch rivets and works for 1/8-inch rivets. instructional rivet removal tool cleco trick pliers builders aircraft unique Measure your pattern and mark the hole locations with a permanent marker. Others use a rivet set activated by a dead blow hammer. Once you get the feel for it, you can do it without damaging the hole, but dont try it for the first time on something you want to keep. Secure the pieces of metal to be riveted, with clamps if possible. Line up the pieces of material that you are going to join. Damaged rivet head or material due to the rivet gun set being allowed to come-away from the rivet during the setting process. In the meantime, you will need to use a bucking bar, or some type of flat metal bar, to hold the rivet head in place. Here is what you want to achieve in the finished joint: Rivet-setting pressures are high. Solid rivets come in many different metals and alloys, but the ones most commonly used by Experimental builders are made of aluminum or Monel. It is easier to see the rivets with rivet tape, but blue masking tape is cheaper and works well enough. Allowing the set to come away from the rivet during successive drives will guarantee distortion of either the rivet, the material, or both. Rivet dies for countersunk rivets will be flat, while protruding-head rivet dies will be concave. Place the head of the rivet inside the dome hole of the rivet snap so the pin is facing upwards. If any rivets are loose or move around too easily, you will need to give them another punch with the air hammer. You will have to drill the hole to a larger size and use a bigger rivet if you damage the hole, so be careful while removing rivets. EAA Canada Council Attends COPA's National Fly-In. These metals will be found almost exclusively in the firewall area of most planes. They will need to place the air hammer bit on the end of the solid rivet to easily hammer it flat onto the metal surface. Defective rivets will result from: As stated before, every rivet is a challenge and deserving of an inspection to affirm its suitability. This squeezer is useful for -3 rivets and can also be used for -4 rivets, but most people will find the large hand forces for a -4 rivet are difficult to achieve. Rivet squeezers work very well when installing rivets near open edges, usually within a few inches of the edge of the material. This hole should just fit over the set rivet, and the height of the rivet should be about equal to the thickness of the gauge material. If you add that to the two sheets of .032-inch aluminum, you get a total length of .252 inch or about inch. Monel universal head rivets carry the designation MS20615. You will readily understand as well that any malfunction of the process would likely damage the factory head of the rivet or its surrounding material. Your choice of setting your solid rivets will depend on your confidence with each of the above methods. One can argue about whether these are the best tools for the job, but they represent a good place to get started for the first-time builder. Try to maintain a pattern where you are always riveting the midpoint between the rivets that have already been installed. Rivet squeezers come in a variety of types.

Aluminum AD rivets come in these main configurations: universal head (similar to but not exactly the same as round-head), designated as AN470AD or MS20470, and flush or countersink rivets that are shaped to fit in a 100-degree countersunk hole, designated as AN426AD or MS20426. Place the drill bit at the centre of a marked point. Back riveting is a popular way to drive flush rivets. huck bobtail A solid rivet is a good way to attach two pieces of metal together without the use of welding. In the case of flush rivets, the hole is countersunk or dimpled after drilling to accommodate the flush head. As an alternative, other builders apply tape to the end of the rivet set. Hand squeezers work well for a few rivets, but pneumatic squeezers provide welcome relief for hands and arms if a lot of rivets are to be squeezed at one sitting. The T4 heat treatment that they come with is very stable over time and cannot be duplicated or modified in the field. The countersink is the correct size if the rivet sits flush. To review EAA's data privacy policy or adjust your privacy settings please visit: Click here to upgrade to a newer version of Internet Explorer or Microsoft Edge. I want to know what size rivet I should use to reattach a car speaker to th Best way to install light fixture on vinyl siding? Best practices will entail doing this correctly, with the correct rivets installed at the correct spacing and edge clearance. 2021 Wonkee Donkee Tools. Drill the rivet holes. This axial force must be applied to the rivet in order to mushroom the shop head concentrically. A variation of the hand squeezer uses a compound action that increases forces to the rivet as the squeezing motion reaches the latter part of its travel, allowing the setting of a -4 rivet with relative ease. This is an ideal setup for back riveting smaller pieces. Deburr the holes with a debburing tool. This completes our look at setting (or driving) solid rivets. This one uses a lever with an over-center design.

Finally, the components cannot be allowed to move relative to each other during the setting, or the rivet or the forces applied to the rivet will tend to deform the material and not the rivet. When properly squeezed or driven, the shop head of a solid rivet should be one-half the rivet diameter in height and 1.5 times the rivet diameter in width. If you actually have more than a very few 5/32-inch rivets to drive, you really need a 4X gun, but this would not be likely for most amateur airplane builders. This simple exercise will produce the level of confidence needed to proceed with your project. Countersink the rivet holes if needed. Once the holes are all drilled, you can then begin to insert the rivets. It is limited, though, by the depth of the throat of the squeezer.

Bucking bars are used to form the shop heads on driven rivets. Monel has a melting point of about 2400F, versus aluminum at 1040F. He will hold a heavy metal bucking bar against the tail of the rivet and signal you to start riveting. As well as inspecting for the above defects, you will want to know if it meets the size tolerance criteria of item 1 above. You should build a simple gauge (Figure 9) that allows quick and easy confirmation of the correct setting dimensions. All information is provided "AS IS." Repeat for each hole, then remove the material from the jaws of the vice. Reverse the hammer and used the ball end to tap the expanded pin. Inspect the rear of the rivet for a properly formed head. When this happens, the rivet will have a stronghold. Only after feeling that pressure should the riveter press on the trigger of the rivet gun. Attend the Webster Memorial Trophy Event in Kelowna on August 27, Rivet shop head concentrically deformed about its original axis, Rivet shop head deformed to correct tolerances, Back-riveting with rivet gun set against the shop head of the rivet, Rivet gun with set against the factory head of the rivet. It is also important to choose the correct size die. Rivets must be squeezed or driven (basically pounded) into shape by any one of a number of appropriate tools.

Get a volunteer to work on the other side of the project with an air hammer. Support the material on the back side, and using the pin punch drive the remaining rivet shank out. Keep the drill perpendicular to the material being drilled, and hold the drill steady so that the holes do not become oval-shaped or elongated. It is best to practice this on pieces you arent using in your project. An alternative to the squeezer is the rivet frame. The decision to dimple or countersink should be based on the thickness of each piece of material being joined. A back-riveting plate set in a carpeted tabletop. The EAA website is currently undergoing maintenance. All rights reserved. You can read about an interesting experiment to test the strength of rivets set well and not so well in an article written by Bill Marvel here. These installations can be removed or uninstalled, but this has to be done with a drill, not a screwdriver or ratchet, as with screws or bolts. Adjustment of the air regulator on the air supply to the gun, and 2. All Wet?The Freedom article by Roy Beisswenger (KITPLANES, July 2013) is only half a 2022 Kitplanes.com. What Are The Different Types Of Blind Rivet? Whatever tools you use, the process begins with a clean hole through two or more pieces of metal or other material. When all else fails, the pneumatic rivet gun and bucking bar can usually get the job done. Since we covered blind rivets in a previous article, we will focus on solid aircraft rivets in this article. Pick up your second rivet snap again and place it with its dome shape on the expanded end of the rivet. If you consider that deformation must occur at a value above the yield strength of the rivet, you can calculate that the setting force of a -3 (3/32-inch diameter) rivet is in the order of 345 pounds and of a -4 (1/8-inch diameter) rivet, 615 pounds. With a working depth of up to two feet, the rivet frame will allow work to be done far away from the edge of the material. Tap the rivet snap several times to shape the head of the rivet, giving it a professional finish. This rivet is a fastener that is a solid tube with a head that resembles a flat screw. Install an appropriate rivet die into a rivet gun. The downside is that they are rather expensive.

They are particularly popular for dimpling fuselage and wingskins prior to installation of flush rivets. A 3X gun is ideal for 1/8-inch rivets, but also works well with 3/32-inch rivets and marginally on 5/32-inch rivets. Once the holes have been completed, you should go over them with a very light coating of oil to prevent any rust from developing. Learn how your comment data is processed. rivets anvil rivet We apologize for any inconvenience. There are different ways to install a solid rivet into a workpiece, but they all depend on making a mushroom end so that it holds the two pieces together. Inspect the front and back of the rivet for damage. You can used the second rivet snap to ensure the two pieces of material are forced as close together as possible before fixing the rivet. Squeeze the trigger of the rivet gun only when the rivet bucker signals you to do so. Needless to say, the countersink cutter needs to be held squarely with the hole to produce an even recess for the flush rivet head. The set is then held to the factory head and the rivet is driven by a series of impact blows from the gun against a restraining bucking bar held against the shop head of the rivet. For example, if you need a 3/23-inch flush rivet that is 7/32 inch long, you can order an AN426AD-3-3.5 rivet. Make sure that the rivet is correctly centered on the die before driving it.

They are particularly popular for dimpling fuselage and wingskins prior to installation of flush rivets. A 3X gun is ideal for 1/8-inch rivets, but also works well with 3/32-inch rivets and marginally on 5/32-inch rivets. Once the holes have been completed, you should go over them with a very light coating of oil to prevent any rust from developing. Learn how your comment data is processed. rivets anvil rivet We apologize for any inconvenience. There are different ways to install a solid rivet into a workpiece, but they all depend on making a mushroom end so that it holds the two pieces together. Inspect the front and back of the rivet for damage. You can used the second rivet snap to ensure the two pieces of material are forced as close together as possible before fixing the rivet. Squeeze the trigger of the rivet gun only when the rivet bucker signals you to do so. Needless to say, the countersink cutter needs to be held squarely with the hole to produce an even recess for the flush rivet head. The set is then held to the factory head and the rivet is driven by a series of impact blows from the gun against a restraining bucking bar held against the shop head of the rivet. For example, if you need a 3/23-inch flush rivet that is 7/32 inch long, you can order an AN426AD-3-3.5 rivet. Make sure that the rivet is correctly centered on the die before driving it.  The optimum length for a solid rivet will be equal to the thickness of the material to be joined, plus an exposed tail equal to the rivet diameter times 1.5. When you are just about at the point where the rivet head ends and the stem begins, stop drilling and gently move the drill bit from side to side to break off the rivet head. In any case, this is a skill that airplane builders should have, at least at a modest level. Lengths and diameters are shown in the suffix, with the first number being the diameter in 1/32 inch and the second number being the grip length in 1/16 inch. The rivet gun is an impact type of a tool that provides repeated axial impact forces (think hammer) to deform and set the rivet. Ref: Standard Aircraft Handbook, Larry Reithmaier, McGraw Hill, Sheet Metal Basics, EAA SportAir Workshops, EAA. This will keep things in proper alignment and avoid buckling that could occur if you simply started at one end and kept going. It must completely fail -- break -- or be drilled before it will come out. What Type of Drill Bit to Drill Holes in Flatware? Likewise for a -3 (3/32-inch diameter) rivet, the gauge hole should be about 0.144 inch or #27 drill, and the thickness should be about 0.050 inch. Please enable cookies in your browser. If there has been any swelling of the rivet between the materials of the joint, or if the hole has not been drilled precisely in the centre of the rivet, this will just not happen. Remove faulty rivets by drilling straight through their centers and knocking out the remains of the rivet with a punch. Place and clamp the material on to the platform of the drill press so they are ready to be drilled. This is important if you are rebuilding a classic automobile, or creating something that does not need any strong welds. Use a marker, or a piece of chalk, to draw on your piece where the rivets should go. They can also be used to join titanium parts. to this site, and use it for non-commercial use subject to our terms of use. A number of aviation parts and tool vendors have sets of these tools designed to work well with kits from various manufacturers. A section of RV-8 floor is an ideal piece to back rivet. The parts they secure are usually also made of aluminum, since dissimilar metals tend to speed corrosion when they are in prolonged contact. If the hole size exceeds the maximum, then the hole must be drilled out to the next larger size and a larger rivet used. Improper diameter and/or length of the rivet. Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved. Start by center punching the head of the rivet (the shop head with the dimple in it). If rivet cracks are visible, the strength of the joint is compromised.

The optimum length for a solid rivet will be equal to the thickness of the material to be joined, plus an exposed tail equal to the rivet diameter times 1.5. When you are just about at the point where the rivet head ends and the stem begins, stop drilling and gently move the drill bit from side to side to break off the rivet head. In any case, this is a skill that airplane builders should have, at least at a modest level. Lengths and diameters are shown in the suffix, with the first number being the diameter in 1/32 inch and the second number being the grip length in 1/16 inch. The rivet gun is an impact type of a tool that provides repeated axial impact forces (think hammer) to deform and set the rivet. Ref: Standard Aircraft Handbook, Larry Reithmaier, McGraw Hill, Sheet Metal Basics, EAA SportAir Workshops, EAA. This will keep things in proper alignment and avoid buckling that could occur if you simply started at one end and kept going. It must completely fail -- break -- or be drilled before it will come out. What Type of Drill Bit to Drill Holes in Flatware? Likewise for a -3 (3/32-inch diameter) rivet, the gauge hole should be about 0.144 inch or #27 drill, and the thickness should be about 0.050 inch. Please enable cookies in your browser. If there has been any swelling of the rivet between the materials of the joint, or if the hole has not been drilled precisely in the centre of the rivet, this will just not happen. Remove faulty rivets by drilling straight through their centers and knocking out the remains of the rivet with a punch. Place and clamp the material on to the platform of the drill press so they are ready to be drilled. This is important if you are rebuilding a classic automobile, or creating something that does not need any strong welds. Use a marker, or a piece of chalk, to draw on your piece where the rivets should go. They can also be used to join titanium parts. to this site, and use it for non-commercial use subject to our terms of use. A number of aviation parts and tool vendors have sets of these tools designed to work well with kits from various manufacturers. A section of RV-8 floor is an ideal piece to back rivet. The parts they secure are usually also made of aluminum, since dissimilar metals tend to speed corrosion when they are in prolonged contact. If the hole size exceeds the maximum, then the hole must be drilled out to the next larger size and a larger rivet used. Improper diameter and/or length of the rivet. Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved. Start by center punching the head of the rivet (the shop head with the dimple in it). If rivet cracks are visible, the strength of the joint is compromised. This helps ensure a tight joint. meyette servo elevator autopilot lathe rod trim length control Do not attempt to anneal or in any other way heat treat AD rivets. The oops comes from the fact that they are often used to replace damaged or poorly driven rivets that are then poorly drilled out, producing an oversized hole. The rivet installation is so strong because the rivet is actually flattened around the back of the rivet hole during the riveting process. You will note that in the above description of setting rivets with a rivet gun, the impact of the rivet gun set was always directed at the factory head of the rivet. Next, the individual material pieces need to be firmly clamped together during this setting process so that no intermediate space allows the rivet to swell between the materials. Cookies are required for this site to operate correctly. Monel rivets will be harder to drive and buck than aluminum rivets due to their higher strength and tendency to work harden.

It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. To install solid rivets you will need the following tools; a drill press, drill bit, two drilling machine work grips, a vice, two rivet snaps and a ball-pein hammer. If you are having trouble logging in, please do not reset your password, but try again later.

It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. To install solid rivets you will need the following tools; a drill press, drill bit, two drilling machine work grips, a vice, two rivet snaps and a ball-pein hammer. If you are having trouble logging in, please do not reset your password, but try again later. Two riveting procedures have evolved. Universal head rivets can also be back riveted with a special bucking bar, but the process is much less common. The most common aircraft rivets, known as AD rivets, are made from a hard aluminum alloy. Only complete this step if you will install flush mount or countersink rivets. Drill a hole (same size as the original) into the head of the rivet, using the rivet dimple to help locate the center. Check the countersink by placing a corresponding rivet in the hole. He has so far completed fourtwo GlaStars, a Glasair Sportsman, and a Texas Sport Cuband is helping a friend build an RV-8.

Use the same method on each rivet in turn to finish securing the metal together. They are available in limited sizes with the designation of NAS1097. Tapping this end of the rivet several times will cause the pin to deform and expand, starting to create a second head. 1995-2022 MH Sub I, LLC dba Internet Brands. By the way, you will need hearing protection whenever you use a rivet gun. Insert a drill bit sized for the rivets into a drill. Insert a pin punch into the hole and pry off the head. In that case, the countersink must be large enough to allow the dimpled sheet to set properly into the countersink in the other piece, but not so large as to allow any movement of the dimpled sheet in the countersunk hole. To ensure our content is always up-to-date with current information, best practices, and professional advice, articles are routinely reviewed by industry experts with years of hands-on experience. Avoid overdriving the rivet on initial taps. Copyright Tighten the vice, leaving the end of the rivet snap protruding from the top of the vice jaws. Next rivet each end, and then go to the point midway between the middle and one end.

Then slowly drill straight into the rivet head with a drill that is the same size or slightly smaller than the one used to drill the original hole. All new airplane builders should attend one or more of these classes before starting on their project. At one end of the snap there is a hole and an internal dome (concave) shape, while at the the other end is a flat surface for striking with the hammer. Drill slowly through the material until the drill pierces each piece of material. Tap the pin so it forms a domed head. The back-rivet set is shown here in the rivet gun. // Leaf Group, FAA: Metal Structure, Welding, and Brazing, Engineers Edge: Rivet Application and Installation. Holding the two pieces of material together, place the corresponding holes onto the pin of the rivet. A Rivet frame is very nice for dimpling skins for flush rivets. The set shop head should be 1.5 times the diameter or 3/16 inch, and its height should be 0.5 times the diameter or 1/16 inch. Rivets that didnt come out so well will need to be removed. A small hand deburring tool will do. If the forces applied to the rivet during setting are not axial the material pieces of the joint will tend to move relative to each other. This allows much more confidence in achieving an aesthetically pleasing surface to your project. View our Privacy Policy here. Again, it is very important that the operation begins with the rivet set holding the factory head tightly to the material and that the bucking bar pressure on the rivet be increased as the rivet is set. They should be spaced every couple of inches for the best holding power. Both the rivet gun and the bucking bar must be held so as to ensure that the impact forces are axially applied to the rivet (Figure 5). Rivet tape (shown here) or blue masking tape helps hold rivets in place and protects the skin around the rivets.