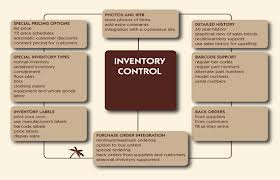

* The application of computer system in inventory control is to ensure that immediate availability of much more complete data for use in making purchasing and related material decisions because of its speed. MIS tools move data and manage information. Radio Frequency Identification (RFID) System. Today, a range of computing devices funnel important data from a variety of sources, from sales to time cards to inventory. The purposes of this research were to study the inventory management factors affecting the competitive advantageand confirm the inventory management factors affecting the competitive advantage. Light Fidelity (LiFi) Technology. More than 10,000 Wal-Mart retail suppliers used the retail link system to monitor the sales of their goods at stores and replenish inventories. They form the basis for operations. A smart inventory control module will also alert you when it's most advantageous to re- order stock. Overstocking will lead to cash flow blockage and the additional cost for managing excess stock. Asset Panda can handle any number of hardware and software assets, and its available both online and through a mobile application. Significance of inventory in logistics and supply chain management is its ability to make the demand from the end customers side to be Real-Time Management Information. Although cost savings were found, they were not substantial compared to our previous system (less than $5,000). 4.0. 26 (2); 106 - 116. Material requirements planning (MRP) is a production planning and inventory control system. Radio Frequency Identification (RFID) System. By keeping in view the developments, the business experts can spell and forecast the success and failure in todays competitive environment. SCMS makes lean manufacturing processes such as just-in-time inventory practical. Inventory management, therefore, plays a vital role in balancing the benefits and disadvantages associated with holding inventory.

A robust solution provides easy accessibility, allowing you and warehouse personnel to check on inventory levels from a laptop, tablet or another mobile device.  Apr 16, 2019Try Smartsheet for FreeGet a Free Smartsheet Demo. In 1991, Wal-Mart had invested approximately $4 billion to build a retail link system. The CODP is the point where product specifications get frozen in most cases, and more important, it is the last point at which inventory is held .Thus, the inventory at the CODP is a strategic stock point since delivery promises are based on the stock availability at the CODP and the lead times and capacity availability for the customer order-driven operations downstream the

Apr 16, 2019Try Smartsheet for FreeGet a Free Smartsheet Demo. In 1991, Wal-Mart had invested approximately $4 billion to build a retail link system. The CODP is the point where product specifications get frozen in most cases, and more important, it is the last point at which inventory is held .Thus, the inventory at the CODP is a strategic stock point since delivery promises are based on the stock availability at the CODP and the lead times and capacity availability for the customer order-driven operations downstream the

By using it, your company can rapidly generate higher sales and increase productivity to meet yearly objectives. The three primary objectives of controlling inventory are to manage levels, safeguard inventory and to report it correctly on financial statements.

It helps a business make well-informed pricing, manufacturing, marketing and purchasing decisions. risk management as an emerging core competency, many also see the need for better data and information, so their organizations can take action on an ever-evolving inventory of risks. Inventory can be acquired by a business and sold to customers without change to the product.

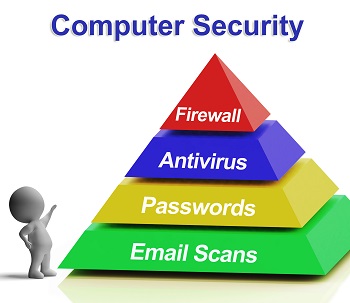

This is where inventory management comes into play.  Cargo handling is a very important part of logistics, and losses in cargo handling directly increase logistics costs. Inventory management training makes good business sense because it improves the productivity and efficiency of your employees. #5 . They develop inventory management systems, maintain stock levels, and coordinate the logistics of orders and transfers. Intrusion Detection Systems (IDS) use several techniques to protect networks. Computers, Informatics, Nursing. The role of demand forecasting in inventory control. Further, to help with vendor We now show how on-hand inventory evolves differently under two policies.

Cargo handling is a very important part of logistics, and losses in cargo handling directly increase logistics costs. Inventory management training makes good business sense because it improves the productivity and efficiency of your employees. #5 . They develop inventory management systems, maintain stock levels, and coordinate the logistics of orders and transfers. Intrusion Detection Systems (IDS) use several techniques to protect networks. Computers, Informatics, Nursing. The role of demand forecasting in inventory control. Further, to help with vendor We now show how on-hand inventory evolves differently under two policies.  It automates the key business processes and guides you to make smarter decisions. It also includes the most relevant tools and free templates for IT asset management (ITAM). The retail industry faces many specific challenges related to IT management, including: Customer data. It covers the whole asset lifecycle, from procurement to disposal.

It automates the key business processes and guides you to make smarter decisions. It also includes the most relevant tools and free templates for IT asset management (ITAM). The retail industry faces many specific challenges related to IT management, including: Customer data. It covers the whole asset lifecycle, from procurement to disposal.

Inventory management is the supervision of non-capitalized assets (inventory) and stock items.

Materials Requirement Planning - MRP: One of the first software based integrated information systems designed to improve productivity for businesses. Manual: If a computer account is present in Active Directory, it can be added to the server inventory. Setting up roles. The advent of computers enabled Operations Management to gain the more widespread use it enjoys today. Inventory control is a system of ordering based on the maintenance of the stock in a store using a re-order rule based on the stock level. Information technology in inventory management acts as a tool for enhancing efficiency and cost reduction. Inventory Management Concepts. Susan P. Kossman and Sandra L. Scheidenhelm (2008). It is software installed on the computer systems that enables a firm to keep a check on the inventory levels by performing the automatic counting of inventories, recording withdrawals and revising the stock balance. Role of computer in business. Computers make peoples lives easier and more comfortable: they provide opportunities for staying in touch to billions of people who may very well be in different parts of the world. Inventory control and monitoring systems are accounting approaches to track the number of goods on hand. Big companies often monitor inventory across stores, warehouses and even websites. The two main systems are periodic and perpetual tracking systems. The Periodic System vs. the Perpetual System The role of production planning and control in the manufacturing industry is to ensure that materials and equipment are available when needed and that everything runs smoothly. Informed by the educational conditions shaped by the novel coronavirus pandemic and an increased reliance upon online learning solutions and technologies, this article examines the role of personality traits and online academic self-efficacy in acceptance, actual use and achievement in Moodle on a socially distanced asynchronous university course in Japan. The primary objective of this research work, the application of computer technology on the inventory control system as a productivity improvement strategy in Niyya Farm Nigeria limited Kaduna is to carry out paper investigation as regards the awareness and reaction of people concerning the project topic, taking Niyya Farm Kaduna as a case study. Healthcare supply chain management refers to obtaining and organizing all the necessary products which enable proper functioning of a healthcare organization and providing patients with the necessary treatment. The Chair of the Committee on Information Technology should: 6.1 Develop citywide information technology inventory management policies, procedures and standards. The efficiency of the inventory control increased dramatically (50%) after project implementation. This guide provides the most comprehensive discussion of best practices for maintaining clear, accurate, and updated asset inventory data in order to support change and growth. One is called a "halt", which stops the hacker from progressing into the network. At the same time, this control also involves the calculation of the warehouse stock. The benefits of proper guidance and training is ultimately to manage inventories effectively in terms of stock levels, operational efficiencies and customer service delivery. Inventory turnover is a ratio showing how frequently a business has purchased and sold inventory during a given period. 2. The practice of managing inventory has always been very costly for businesses. Warehousing and distribution face unprecedented pressures from COVID-19 disruption, commoditization, labor shortages and rising customer expectations. It concerned with three forms of inventory that is Raw materials, In-process or semi-finished goods, and Finished goods. With the help of adequate records the firm can protect itself against thefts, wastes and leakages of inventories. Its important to choose a solution that is Component traceability and procurement has special challenges in the electronics industry that require diligent planning. RFID technology improves inventory accuracy by 98 percent or more, reducing costs and improving efficiency from end-to-end while enabling automated processes and creating new efficiencies that drive profits. Mobile Device Manager: Mobile Device Manager role has write permission for the following, Inventory, Reports, Profiles and Apps in Mobile Device Management.

Inventory controllers, or stock controllers, manage inventory levels for businesses in a variety of industries, including retail, commercial, and industrial. Asset Pandas customer service is US-based, and anyone can test this popular computer inventory software solution for up to 14 days for free. Work cross-functionally with all departments to deploy and ensure adherence to inventory policies; solicit input for improvement and drive cultural change. You'll also find links to Intune, Conditional Access, BitLocker keys, and basic monitoring. Computers, Informatics, Nursing. In 1991, Wal-Mart had invested approximately $4 billion to build a retail link system. Warehouse automation is an effective way to gain efficiencies, cut costs and scale operations. Automating all your inventory management functions, an Inventory Management Software is a computer-based solution that provides an organization with a comprehensive solution for their Effective Information Management. It enables a company to provide better services to its customers. The following are the reasons why information technology is important for the supply chain: 1. Budgeting plays a crucial role in planning and control. Computers can play role like,

With the development of technology and availability of process driven software applications, inventory management has undergone revolutionary changes. One benefit of a POS system is that it simplifies communications between the kitchen and the wait staff. Essentially, information technology can speed up processes and deliver cost saving benefits to the company. Information Technology in Supply Chain or Logistics. Main Inventory Control System Types: Perpetual Inventory System.

The technical stack within your organization should also enhance inventory management. Use of information technology in supply chain management provides improved visibility and accountability. Here are some essential metrics to keep in mind when creating a stock report: 1. This does not only include medical products. Maintain customer happiness. Information systems are the tools, hardware and software that help retailers achieve success in a dynamic environment. The use of information technology (IT) is considered a prerequisite for the effective It enables a company to provide better services to its customers. The goals of hardware asset management are to account for all hardware assets on the IT infrastructure to provide comprehensive inventory visibility. An inventory control system is a system the encompasses all aspects of managing a company's inventories; purchasing, shipping, receiving, tracking, warehousing and storage, turnover, and reordering. Managing inventory control. Know more on how information technology in inventory management helps in the article below: Just-in-time inventory is the application of the just-in-time (JIT) method to inventory management. Technicians can help keep track of your pharmacys top 50 dispensed medications and determine not only the frequency at which to order but also the quantity. choice #5. 3) RFID stock tagging and tracking. From tracking inventory to creating bills of materials to scheduling production, the MRP systems (and later the MRP II systems) gave more businesses a reason to want to integrate computing into their processes. Integrate your entire business. Posted 4:46:03 PM. However, the process is a little more complicated than this. Inventory Control is designed to support the requisition processing, inventory management, purchasing, and physical inventory reconciliation functions of inventory management through a set of highly interactive capabilities. The inventory specialist is the key user of the stores inventory management software. One of the greatest advantages of a computerized inventory system is that it makes for faster, more accurate counting. Inventory management, therefore, plays a vital role in balancing the benefits and disadvantages associated with holding inventory. Physical warehouse automation is costly. It helps the business keep automatic track of inventory, streamline ordering and track items throughout the product sale cycle. A paper published 2002 by SCORE (Counsellors to Americas Small Business) suggest that inventory control systems range from eyeball systems to reserve stock systems to perpetual computer-run systems. From these books summary of transactions and financial statements are prepared manually. The new powerful computer programs manages the great volume data and keep the records that needs, including inventory control systems. Inventory - This plays a major role in the success or failure of a supply chain, so it is important to coordinate this throughout a supply chain Stock control, otherwise known as inventory control, is used to show how much stock you have at any one time, and how you keep track of it..

The Factors of Inventory Management of Food-Processing-and-Distribution Industry In the food-processing-and-distribution industry, a company uses a set of techniques to transform ingredients into foods or to transform foods into other products for consumption by consumers (Connor, 1988). The role of this inventory type is to enable the company to satisfy expected seasonal increases in demand. Inventory is often the largest asset a company has. Inventory tracking result in a better bottom line and a more profitable business. Managing adequate stock is key for managing inventory successfully. IIoT. Perhaps the most important advantage of inventory management is saving a company money. The role defines which reports and panels the user can view. It had 2,000 computers in finished goods inventory at the end of the last year. Intentions of Hospital Nurses to Work With Computers Based on the Theory of Planned Behavior. To me, the benefits of inventory management software are very clear: Achieve efficiency and productivity in operations. Increased Control Over Production. Inventory controllers, or stock controllers, manage inventory levels for businesses in a variety of industries, including retail, commercial, and industrial. You may be able to carry less inventory or even go to a full-blown, just-in-time inventory system, with product arriving from your vendors as its needed. Types of Inventory Management Systems within Inventory Control Systems: Barcode System. Minimise inventory costs and maximize sales & profits. Scalability Your eCommerce business might be small now, but youll continue to grow, and you need an inventory management system that can handle that growth. Receipt of Goods The main goals of asset management are: keeping track of the companys assets.

To Develop Policies, Plans and Standards Required: So as to achieve the inventory control objectives. Supermarket Inventory Control. Inventory control management. The computer group narrows down the scope of these reports and panels to computers that meet certain criteria. To effectively manage the flows in the supply chain, companies have to deal with upstream supplier exchanges and downstream customer demands. Save Money. Providing wireless connectivity for a large number of robots and electronic devices is a challenging problem in warehouses and factories. Orders go through the computer, directly to the kitchen printer. Another benefit of a restaurant POS program is that it can track everything from food usage to the most popular menu items. In the devices overview, you can view the number of total devices, stale devices, noncompliant devices, and unmanaged devices. Especially the production of information processing inventory control to keep the latest information about the remaining inventory of raw materials and finished goods used to determine the value of inventory and stock status.

Inventory control or stock control can be broadly defined as "the activity of checking a shop's stock". 26 (2); 69 - 77. This software, running on a mainframe computer, gave companies the ability to manage the manufacturing process, making it more efficient. In past decades, most companies had a few computers that served as information hubs. The role of IIoT in inventory management boils down to turning the data fetched by RFID readers into meaningful insights about inventory items location, statuses, movements, etc., and giving users a corresponding output. The Industrial Revolution brought Operations Management into common practice among management. Management information system involves the information system and the organization. a. Each robot is compactly designed, meaning you can operate in a smaller warehouse, with up to a 90 per cent reduction in necessary floor space. More than 10,000 Wal-Mart retail suppliers used the retail link system to monitor the sales of their goods at stores and replenish inventories. Manually entering data into a spreadsheet or tracking stock using pen and paper increases the risk of inventory mistakes. It applies to every item you use to produce a product or service, from raw materials to finished goods. 6.2 Develop a citywide plan for replacing and upgrading General Fund department information technology.

Call on +44 (0) 121 517 0008. Management of Inventory. The benefits or importance of inventory control is listed in following points: Inventory control protects a company from fluctuations in demand of its products.

Inventory control software simplifies the management of pricing products and helps maintain the most effective stock levels. They develop inventory management systems, maintain stock levels, and coordinate the logistics of orders and transfers. But a large inventory has its own liabilities the cost to store and insure it, and the risk of spoilage, theft and damage. It covers stock at every stage of the production process, from purchase and delivery to using and re-ordering the stock. With a Stock control consists of all the activities and processes undertaken to track inventory levels, place orders and to ensure adequate quantities of each item is held in stock. Inventory management is where all the elements of the supply chain converge. The main work in cargo handling is separated into six tasks: assortment, stacking/taking inventory, transportation, storage (allocation), sorting, and picking. Increased productivity and efficiency.

Role of Computers in Accounting: The manual system of recording accounting transactions requires maintaining books of accounts such as journal, cash book, special purpose books, and ledger and so on. An inventory specialist uses this software for almost every aspect of their role, from determining order quantities to maintaining a stores inventory budget. Role of Information Technology in Inventory Management. The role of the Inventory Control Specialist I is to ensure that product is available for sale, toSee this and similar jobs on LinkedIn. Importance of inventory control. LiFi is a technology for wireless communication between devices using light to transmit data and position. Maintaining consistent levels of inventory gives companies a good idea of how their businesses are running. These tasks greatly effect productivity and quality in logistics.

Role of computer in business. Inventory management and supply chain management are the backbone of any business operations. Retailers are beginning to notice that technologys role is one of an enabler. Definition: A Computerized Inventory Control System is the integration of sub-functions involved in the management of inventory into a single cohesive system. Today people can drive computerized cars and work for employers from other countries without even seeing them. Inventory Management Assignment Instructions Research two (2) manufacturing companies that manage inventory and complete this assignment: Write an eight (8) page paper in which you: Determine the types of inventories these companies currently manage and describe their essential inventory characteristics. An Inventory Management Software is a computer-based solution that provides your organization with a comprehensive solution for inventory management requirements. Effective information management can help ensure that a firm meets the logistical needs of its customers. An MRP integrates data from production schedules with that from inventory and the bill of materials ( BOM ) to calculate purchasing and shipping schedules for the parts or It keeps a smooth flow of raw-materials and aids in continuing production operations. Information technology provides control and overview over the inventory and hence helps in avoiding many bottlenecks. Inventory control results in the maintenance of necessary records, which can help in maintaining the stocks within the desired limits. If you add a server manually, at least one server role (domain controller, DNS server, DHCP server, or NPS server) must also be selected manually. Inventory software lets you know exactly what you have on hand and where to find it. Types of Inventory Management Systems within Inventory Control Systems: Barcode System.

The role of the Inventory Control Specialist I is to ensure that product is available for sale, toSee this and similar jobs on LinkedIn.

One of the key functions of an Inventory Management Software is that it makes the process of managing your inventory a whole lot easier saving time and money. Robots can help with stock management and picking-and-packing. Distribution System 46. OS Deployer: The OS deployer role provides the associated user the privilege to capture images of Windows OS and deploy it across the network computers. Inventory can be a companys most important asset. A system with four important features can help simplify and streamline inventory management: Real-Time Product Updates As customers order items, real-time updates enable you to accurately manage warehouse product levels and keep your eCommerce site up-to-date. Argues that the mathematical techniques embodied in existing computerbased inventory management systems software have not kept pace with developments.