The quiz will be based on the entire course document. The control and instrumentation course involves an extensive understanding of current loops and the devices typically found on them. This course is also available upon request as a private, on-site seminar. With our hands-on training, you can ask questions to an experienced instructor. This PE continuing education course is intended to provide you with the following specific knowledge and skills: In this professional engineering CEU course, you need to review the course document titled, "Introduction to Electrical Code, Drawings, Controls and Lighting Systems" which is based on the principles in the book Electrical Engineering for Non-Electrical Engineers, S. Bobby Rauf, Fairmont Press, 2013. New hires may assist experienced engineers with using programming systems to integrate additional manufacturing machines into existing production lines. They are shown how auto-tuning is activated and they can then contrast and compare this with the advantages and disadvantages of manual tuning. Klenke received his BSEE degree from the Virginia Military Institute in 1982 and his MSEE and Ph.D. (Electrical Engineering) degrees from the University of Virginia in 1989 and 1993 respectively. You'll see the education requirements and learn about the experience you need to advance your career in engineering. Enter zip:  Candidates on the control and instrumentation course then learn about the various devices used in industrial temperature measurement systems - we concentrate on thermocouples and Pt100s and their associated cabling, connectors and transmitter heads. 100% online.

Candidates on the control and instrumentation course then learn about the various devices used in industrial temperature measurement systems - we concentrate on thermocouples and Pt100s and their associated cabling, connectors and transmitter heads. 100% online.

The next set of practical exercises are based on temperature control loops. Weve designed our training to be modular, customizable, and support a wide variety of platforms in order to meet your unique needs. Other duties may include installation specifications and coordinating end user support. Candidates look in detail at the devices used to measure temperature, pressure, level and flow, and briefly at control valves, load cells, turbidity, density and pH, then go on to study the devices commonly used to control industrial processes. Allen-Bradley CompactLogix / ControlLogix.

The next set of practical exercises are based on temperature control loops. Weve designed our training to be modular, customizable, and support a wide variety of platforms in order to meet your unique needs. Other duties may include installation specifications and coordinating end user support. Candidates look in detail at the devices used to measure temperature, pressure, level and flow, and briefly at control valves, load cells, turbidity, density and pH, then go on to study the devices commonly used to control industrial processes. Allen-Bradley CompactLogix / ControlLogix.

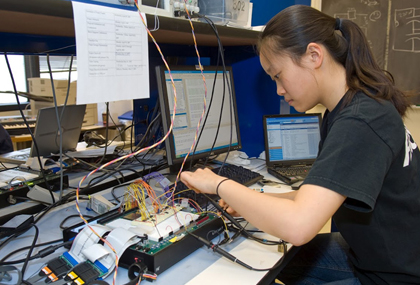

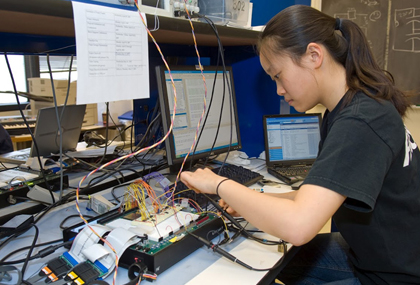

Further, the reader is introduced to common industrial and commercial electrical power rate schedules. Students must be at least 14 years old and have completed the 8th grade. The course is extensively hands on, giving participants considerable practical experience of the devices typically found in industry. 29 Jul 2022 accessed. This 11 PDH online course is applicable to engineers of all disciplines, as well as technicians, facilities managers and executives who are not intimately familiar with electrical engineering principles and practices. Industrial pressure transmitters are then connected on to current loops and calibrated using the pressure sources. For example, we would look in detail at what signals a thermocouple produces, but only very briefly at how it works. The focus is to understand terminology, concepts, typical equipment configurations, and common pitfalls in order to improve communication with electrical and I&C professionals. https://t.co/QPhkIMY7KC https://t.co/MBAQlfE05O, If youre at the #VTEEA Conference today, stop by our booth in the Lord Fairfax room! They also calibrate these devices using a range of professional industrial Time Electronics current calibrators, used throughout the instrumentation engineering world. document.write(document.lastModified.substring(0, View the complete listing of Engineering and Manufacturing courses>, Back to Professional Development: Engineering homepage. Electrical and mechanical engineers need a basic understanding of controls systems and automation. Industrial control systems (ICS) are at the heart of industrial automation, playing a critical role in managing the operations of critical infrastructure, such as power grids; financial networks; and transportation, telecommunications, and manufacturing systems. One of the flow rigs used on the control and instrumentation training course: This one uses an inverter drive controlling a variable speed electrical pump. Engineers Project Engineers Technicians and Supervisors Involved in the Design, Maintenance and Testing of Control Systems and Industrial Automation System Integrators of OEM Equipment Staff Whose Responsibilities Include Commissioning and Troubleshooting of Control Systems Project Managers and Others Who Would Like To Know More About Control Systems and Automation. For further practice at using the pressure sources, candidates on the control and instrumentation course then connect and calibrate a range of industrial pressure switches. This course covers similar content to our E3 and IC3 courses, but at a more conceptual level. All the tools needed by the candidates to make the electrical and pneumatic connections to the devices involved in the practical exercises are provided by us. Sign up for our monthly newsletter! Ability is the flagship organizational management tool, combining a powerful learning and compliance management engine with a competency development and assurance engine. What is your highest level of education completed? EPIC has many catalogs you can download containing courses in your area! One of the flow rigs used on the control and instrumentation training course: This one uses an air powered control valve. 2022 International Society of Automation, Certified Automation Professional (CAP), Control Systems Engineer Technical Reference Handbook, Control Systems Engineering (CSE) Study Guide, Fifth Edition, Control Systems Engineering Exam Reference Manual: A Practical Study Guide, ISA Process Measurement & Control Division, Instrumentation maintenance and troubleshooting, Introduction to Industrial Processes, Measurement and Control (, Fundamentals of Industrial Process, Measurement\, and Control (, Developing and Applying Standard Instrumentation and Control Documentation (, Troubleshooting Instrumentation and Control Systems (, Designing and Tuning Feedback and Advanced Regulatory Control Strategies (, Designing and Applying Model-Based Control Strategies (EC60), Batch Control Using the ANSI/ISA88 Standards (, Certified Control Systems Technician (CCST) Level I Exam Review Course (, Certified Control Systems Technician (CCST) Level I Exam Online Review Course (, Certified Control Systems Technician (CCST) Level II Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Online Review Course (. Dates coming soon! How Do You Get an Engineer Driver Certification? Can You Get an MBA and Work As an Engineer at the Same Time? We use a range of flow rigs (each designed to require different tuning parameters) to demonstrate the alternative methods of system control used in industrial systems; electronic variable-speed drives, electrical control valves and air control valves. A mixing engineer requires some formal education. In summary, the road to becoming a controls engineer includes earning a bachelor' degree, finding entry-level work, obtaining licensure, and being granted the official designation of a professional engineer. In addition, ISA provides comprehensive study materials and review courses for those preparing to take theControl Systems Engineer (CSE) Professional Engineer (PE) examination. Research University of Pennsylvania's Programs & Degrees, Research Stanford University's Degree Programs, Research Duke University's Degree Programs. In 2015, Dr. Klenke developed the first course in Industrial Automation to be taught at VCU. ), Introduction to Electrical Codes, Drawings, Controls and Lighting Systems (5.9 MB), Understanding of the National Electric Code (NEC), Understanding the NEC's role inthe safe design of electrical power distribution equipment, Understanding the NEC's role in theO&M of electrical power distribution equipment, Familiarization with commonly used electrical drawings, Knowing the relationship between electrical power distribution drawings and the NEC, Understanding how PLC's function, their key components and how they are programmed, Exploring cost saving ideas related to electrical power in the industrial/commercial sector, Understanding of lighting metrics, concepts and principles, Understanding of light sources and lighting system design. The minimum passing score is 70%. Covers industrial machine and LAN/WAN network interfacing. The rigs used have a heater, the temperature of which is measured by a Pt100 connected to the controller's input. Contact ISAfor more information. He has over 35 years of combined military, education, and consulting experience in engineering and has published over 85 refereed papers and book chapters. Candidates connect, configure and calibrate a smart device using hand-held programming units, allowing them to experience how modern instrumentation is calibrated. Basic computational methods and illumination analysis associated with lighting system design are presented. ISA offers comprehensive control systems training across essential areas, including: All ISA control systems training courses deliver practical instruction that can be immediately applied in the workplace. This site uses cookies to store information on your computer. There is no time limit on the quiz, and you can take it multiple times until you pass at no additional cost. document.lastModified.indexOf(' '))); Dr. Klenke led the efforts to develop computer engineering as a separate degree program in the Department of Electrical and Computer Engineering which was first ABET accredited in 2005. What Is an Engineer in Training Certification? Learn about machine safety regulations and standards based on OSHA, IEC and other documentation. The course notes are quite extensive and explain how the various devices are used, without getting involved in the underlying theory. Candidates connect up various sensors, looking at the signals that they produce and build current loops around the relevant transmitters. Digest courses at your own pace from the comfort of your own home or office. Innovators Across America Compete Using Stratasys 3D Printers, K-12 Industry 4.0 Career Pathways Programs Are Taking Off. Some sample pages from the course notes give an indication of this approach, the following pages describing how burden resistors are fitted to the rear panels of instruments, what industrial temperature sensors and transmitters actually look like, our own specially-designed calibration tables for thermocouples, the use of dp cells, how hydrostatic pressure measurements are converted to level measurements using pressure sensors and how manifolds are used to zero dp cells used in flow metering: Colour handouts are issued to candidates when necessary - for example when looking at the complex colour-coding systems used for thermocouple cables and connectors: The course involves connecting various devices into current loops so that candidates learn about how current loops work and how devices are connected into them. Learn More. Fundamental computer skills, including working with programs that have an extensive Graphical User Interface is also required. Candidates then learn about pressure measurement: the various units used to quantify pressure and how industrial pressure measurement devices should be calibrated, using industrial pressure sources. Fundamentals of electricity, such as voltage, current, resistance, power factor, and single/three phase power systems, Electrical specifications, such as voltage selection, load lists, and power, How to read one-line diagrams and understand the function of the components of power distribution, including transformers, switchgear, MCCs, VFDs, and power distribution, The function and considerations of infrastructure components, such as cable, conduit, cable tray, and duct banks, Awareness of the concepts behind classification of hazardous locations and equipment specifications, Safety risks and mitigation strategies for power systems, including short circuit and overcurrent protection, ground faults, shock hazards, and arc flash, Fundamentals of control systems, sensors, controllers, and final elements, Key requirements for instrument specifications such as accuracy, signal selection, process conditions, material compatibility, installation considerations, capabilities and limits, and relative cost, Basics of specification of shutdown and control valves, Control system functions, limitations, and architectures, including PLC, DCS, SIS, RTU, and SCADA; common networking systems, including Ethernet, Modbus and Fieldbus, Exposure to the typical documentation and drawings necessary for the design, specification, installation, operation and maintenance of electrical, instrumentation and control systems, Power distribution and motor control systems for oil and gas applications, Hazardous area classification for oil and gas applications, Electrical safety in industrial facilities, Programmable electronic systems (PLC, DCS, SIS, SCADA), Drawings and documentation for IE&C projects. All of ISA's control systems training courses can be taught directly at your company location throughISAOnsite Training services. Contact us if you have additional questions about how to register for or attend this course. We then show candidates how the controllers should be configured, calibrated and tuned so that they give accurate readings and behave well in dynamic situations, explaining the three terms (proportional, integral and derivative) used in common industrial control systems. You can choose from the following delivery options: Our courses are led by published author Frank Lamb, writer ofIndustrial Automation: Hands OnandPLC Hardware & Programming Multi-Platform. Youwill learn the basics of PLC operation, interfacing PLCs to sensors and actuators and programming PLCs for basic control tasks. Track your progress with the discipline progression map. After attaining four years of documented experience, they're qualified to take the second licensing exam, Principles and Practice of Engineering specifically for control systems. A few "low hanging fruit" type electrical energy cost savings opportunities are explored. Proven instructional design methodology and advanced web technology provide effective knowledge transfer for learners. Without consent certain enhanced features will not be available and future visits may require repeated consent, so it is recommended to accept the use of cookies. Controls engineers develop, test, and implement automation, control, and processing systems, such as those used for electrical or water control. Circuit theory and digital processing topics are common in electrical engineering, while mechanical engineering programs may include coursework in materials, thermodynamics, and heat transfer. A degree in engineering is helpful, but not required. Candidates learn about issues like cold junction compensation and three/four wire measurements. Which College Majors Will Guarantee You a Job After Graduation?

Candidates on the control and instrumentation course then learn about the various devices used in industrial temperature measurement systems - we concentrate on thermocouples and Pt100s and their associated cabling, connectors and transmitter heads. 100% online.

Candidates on the control and instrumentation course then learn about the various devices used in industrial temperature measurement systems - we concentrate on thermocouples and Pt100s and their associated cabling, connectors and transmitter heads. 100% online.  The next set of practical exercises are based on temperature control loops. Weve designed our training to be modular, customizable, and support a wide variety of platforms in order to meet your unique needs. Other duties may include installation specifications and coordinating end user support. Candidates look in detail at the devices used to measure temperature, pressure, level and flow, and briefly at control valves, load cells, turbidity, density and pH, then go on to study the devices commonly used to control industrial processes. Allen-Bradley CompactLogix / ControlLogix.

The next set of practical exercises are based on temperature control loops. Weve designed our training to be modular, customizable, and support a wide variety of platforms in order to meet your unique needs. Other duties may include installation specifications and coordinating end user support. Candidates look in detail at the devices used to measure temperature, pressure, level and flow, and briefly at control valves, load cells, turbidity, density and pH, then go on to study the devices commonly used to control industrial processes. Allen-Bradley CompactLogix / ControlLogix. Further, the reader is introduced to common industrial and commercial electrical power rate schedules. Students must be at least 14 years old and have completed the 8th grade. The course is extensively hands on, giving participants considerable practical experience of the devices typically found in industry. 29 Jul 2022 accessed. This 11 PDH online course is applicable to engineers of all disciplines, as well as technicians, facilities managers and executives who are not intimately familiar with electrical engineering principles and practices. Industrial pressure transmitters are then connected on to current loops and calibrated using the pressure sources. For example, we would look in detail at what signals a thermocouple produces, but only very briefly at how it works. The focus is to understand terminology, concepts, typical equipment configurations, and common pitfalls in order to improve communication with electrical and I&C professionals. https://t.co/QPhkIMY7KC https://t.co/MBAQlfE05O, If youre at the #VTEEA Conference today, stop by our booth in the Lord Fairfax room! They also calibrate these devices using a range of professional industrial Time Electronics current calibrators, used throughout the instrumentation engineering world. document.write(document.lastModified.substring(0, View the complete listing of Engineering and Manufacturing courses>, Back to Professional Development: Engineering homepage. Electrical and mechanical engineers need a basic understanding of controls systems and automation. Industrial control systems (ICS) are at the heart of industrial automation, playing a critical role in managing the operations of critical infrastructure, such as power grids; financial networks; and transportation, telecommunications, and manufacturing systems. One of the flow rigs used on the control and instrumentation training course: This one uses an inverter drive controlling a variable speed electrical pump. Engineers Project Engineers Technicians and Supervisors Involved in the Design, Maintenance and Testing of Control Systems and Industrial Automation System Integrators of OEM Equipment Staff Whose Responsibilities Include Commissioning and Troubleshooting of Control Systems Project Managers and Others Who Would Like To Know More About Control Systems and Automation. For further practice at using the pressure sources, candidates on the control and instrumentation course then connect and calibrate a range of industrial pressure switches. This course covers similar content to our E3 and IC3 courses, but at a more conceptual level. All the tools needed by the candidates to make the electrical and pneumatic connections to the devices involved in the practical exercises are provided by us. Sign up for our monthly newsletter! Ability is the flagship organizational management tool, combining a powerful learning and compliance management engine with a competency development and assurance engine. What is your highest level of education completed? EPIC has many catalogs you can download containing courses in your area! One of the flow rigs used on the control and instrumentation training course: This one uses an air powered control valve. 2022 International Society of Automation, Certified Automation Professional (CAP), Control Systems Engineer Technical Reference Handbook, Control Systems Engineering (CSE) Study Guide, Fifth Edition, Control Systems Engineering Exam Reference Manual: A Practical Study Guide, ISA Process Measurement & Control Division, Instrumentation maintenance and troubleshooting, Introduction to Industrial Processes, Measurement and Control (, Fundamentals of Industrial Process, Measurement\, and Control (, Developing and Applying Standard Instrumentation and Control Documentation (, Troubleshooting Instrumentation and Control Systems (, Designing and Tuning Feedback and Advanced Regulatory Control Strategies (, Designing and Applying Model-Based Control Strategies (EC60), Batch Control Using the ANSI/ISA88 Standards (, Certified Control Systems Technician (CCST) Level I Exam Review Course (, Certified Control Systems Technician (CCST) Level I Exam Online Review Course (, Certified Control Systems Technician (CCST) Level II Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Review Course (, Certified Control Systems Technician (CCST) Level III Exam Online Review Course (. Dates coming soon! How Do You Get an Engineer Driver Certification? Can You Get an MBA and Work As an Engineer at the Same Time? We use a range of flow rigs (each designed to require different tuning parameters) to demonstrate the alternative methods of system control used in industrial systems; electronic variable-speed drives, electrical control valves and air control valves. A mixing engineer requires some formal education. In summary, the road to becoming a controls engineer includes earning a bachelor' degree, finding entry-level work, obtaining licensure, and being granted the official designation of a professional engineer. In addition, ISA provides comprehensive study materials and review courses for those preparing to take theControl Systems Engineer (CSE) Professional Engineer (PE) examination. Research University of Pennsylvania's Programs & Degrees, Research Stanford University's Degree Programs, Research Duke University's Degree Programs. In 2015, Dr. Klenke developed the first course in Industrial Automation to be taught at VCU. ), Introduction to Electrical Codes, Drawings, Controls and Lighting Systems (5.9 MB), Understanding of the National Electric Code (NEC), Understanding the NEC's role inthe safe design of electrical power distribution equipment, Understanding the NEC's role in theO&M of electrical power distribution equipment, Familiarization with commonly used electrical drawings, Knowing the relationship between electrical power distribution drawings and the NEC, Understanding how PLC's function, their key components and how they are programmed, Exploring cost saving ideas related to electrical power in the industrial/commercial sector, Understanding of lighting metrics, concepts and principles, Understanding of light sources and lighting system design. The minimum passing score is 70%. Covers industrial machine and LAN/WAN network interfacing. The rigs used have a heater, the temperature of which is measured by a Pt100 connected to the controller's input. Contact ISAfor more information. He has over 35 years of combined military, education, and consulting experience in engineering and has published over 85 refereed papers and book chapters. Candidates connect, configure and calibrate a smart device using hand-held programming units, allowing them to experience how modern instrumentation is calibrated. Basic computational methods and illumination analysis associated with lighting system design are presented. ISA offers comprehensive control systems training across essential areas, including: All ISA control systems training courses deliver practical instruction that can be immediately applied in the workplace. This site uses cookies to store information on your computer. There is no time limit on the quiz, and you can take it multiple times until you pass at no additional cost. document.lastModified.indexOf(' '))); Dr. Klenke led the efforts to develop computer engineering as a separate degree program in the Department of Electrical and Computer Engineering which was first ABET accredited in 2005. What Is an Engineer in Training Certification? Learn about machine safety regulations and standards based on OSHA, IEC and other documentation. The course notes are quite extensive and explain how the various devices are used, without getting involved in the underlying theory. Candidates connect up various sensors, looking at the signals that they produce and build current loops around the relevant transmitters. Digest courses at your own pace from the comfort of your own home or office. Innovators Across America Compete Using Stratasys 3D Printers, K-12 Industry 4.0 Career Pathways Programs Are Taking Off. Some sample pages from the course notes give an indication of this approach, the following pages describing how burden resistors are fitted to the rear panels of instruments, what industrial temperature sensors and transmitters actually look like, our own specially-designed calibration tables for thermocouples, the use of dp cells, how hydrostatic pressure measurements are converted to level measurements using pressure sensors and how manifolds are used to zero dp cells used in flow metering: Colour handouts are issued to candidates when necessary - for example when looking at the complex colour-coding systems used for thermocouple cables and connectors: The course involves connecting various devices into current loops so that candidates learn about how current loops work and how devices are connected into them. Learn More. Fundamental computer skills, including working with programs that have an extensive Graphical User Interface is also required. Candidates then learn about pressure measurement: the various units used to quantify pressure and how industrial pressure measurement devices should be calibrated, using industrial pressure sources. Fundamentals of electricity, such as voltage, current, resistance, power factor, and single/three phase power systems, Electrical specifications, such as voltage selection, load lists, and power, How to read one-line diagrams and understand the function of the components of power distribution, including transformers, switchgear, MCCs, VFDs, and power distribution, The function and considerations of infrastructure components, such as cable, conduit, cable tray, and duct banks, Awareness of the concepts behind classification of hazardous locations and equipment specifications, Safety risks and mitigation strategies for power systems, including short circuit and overcurrent protection, ground faults, shock hazards, and arc flash, Fundamentals of control systems, sensors, controllers, and final elements, Key requirements for instrument specifications such as accuracy, signal selection, process conditions, material compatibility, installation considerations, capabilities and limits, and relative cost, Basics of specification of shutdown and control valves, Control system functions, limitations, and architectures, including PLC, DCS, SIS, RTU, and SCADA; common networking systems, including Ethernet, Modbus and Fieldbus, Exposure to the typical documentation and drawings necessary for the design, specification, installation, operation and maintenance of electrical, instrumentation and control systems, Power distribution and motor control systems for oil and gas applications, Hazardous area classification for oil and gas applications, Electrical safety in industrial facilities, Programmable electronic systems (PLC, DCS, SIS, SCADA), Drawings and documentation for IE&C projects. All of ISA's control systems training courses can be taught directly at your company location throughISAOnsite Training services. Contact us if you have additional questions about how to register for or attend this course. We then show candidates how the controllers should be configured, calibrated and tuned so that they give accurate readings and behave well in dynamic situations, explaining the three terms (proportional, integral and derivative) used in common industrial control systems. You can choose from the following delivery options: Our courses are led by published author Frank Lamb, writer ofIndustrial Automation: Hands OnandPLC Hardware & Programming Multi-Platform. Youwill learn the basics of PLC operation, interfacing PLCs to sensors and actuators and programming PLCs for basic control tasks. Track your progress with the discipline progression map. After attaining four years of documented experience, they're qualified to take the second licensing exam, Principles and Practice of Engineering specifically for control systems. A few "low hanging fruit" type electrical energy cost savings opportunities are explored. Proven instructional design methodology and advanced web technology provide effective knowledge transfer for learners. Without consent certain enhanced features will not be available and future visits may require repeated consent, so it is recommended to accept the use of cookies. Controls engineers develop, test, and implement automation, control, and processing systems, such as those used for electrical or water control. Circuit theory and digital processing topics are common in electrical engineering, while mechanical engineering programs may include coursework in materials, thermodynamics, and heat transfer. A degree in engineering is helpful, but not required. Candidates learn about issues like cold junction compensation and three/four wire measurements. Which College Majors Will Guarantee You a Job After Graduation?