endstream

endobj

818 0 obj

<>/Metadata 83 0 R/Outlines 95 0 R/Pages 815 0 R/StructTreeRoot 100 0 R/Type/Catalog>>

endobj

819 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC]/XObject<>>>/Rotate 0/StructParents 0/Type/Page>>

endobj

820 0 obj

<>stream

I have done simple nameplates on acrylic with with powder coat material (like they use on metal) and an 808nm fiber coupled laser diode. j liked Low-cost and high-speed nanoscale imaging tool. To implement laser etching inside and outside production lines, Laserax offers laser marking machines (for standard solutions) and OEM laser markers (for custom solutions with system integrators). One of the easiest and most common materials that engravers use for paint filling is reverse engravable plastics (usually a clear or frosted acrylic sheet over a thin colored sheet of plastic). Color mapping is useful in two situations - when you want different settings applied to different areas of a design, and when you want to control the order that sections are engraved and/or cut. It might just mean that you should consider stretching your wings a little-just enough to add a splash of color to your work. Looks neat, this allows clear acrylic with selective color. Dust, lint and the like can cause image problems and waste. Just think about it. For laser etching, the material must absorb just enough energy to melt. Also, You would only be able to cut on one surface.

endstream

endobj

818 0 obj

<>/Metadata 83 0 R/Outlines 95 0 R/Pages 815 0 R/StructTreeRoot 100 0 R/Type/Catalog>>

endobj

819 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC]/XObject<>>>/Rotate 0/StructParents 0/Type/Page>>

endobj

820 0 obj

<>stream

I have done simple nameplates on acrylic with with powder coat material (like they use on metal) and an 808nm fiber coupled laser diode. j liked Low-cost and high-speed nanoscale imaging tool. To implement laser etching inside and outside production lines, Laserax offers laser marking machines (for standard solutions) and OEM laser markers (for custom solutions with system integrators). One of the easiest and most common materials that engravers use for paint filling is reverse engravable plastics (usually a clear or frosted acrylic sheet over a thin colored sheet of plastic). Color mapping is useful in two situations - when you want different settings applied to different areas of a design, and when you want to control the order that sections are engraved and/or cut. It might just mean that you should consider stretching your wings a little-just enough to add a splash of color to your work. Looks neat, this allows clear acrylic with selective color. Dust, lint and the like can cause image problems and waste. Just think about it. For laser etching, the material must absorb just enough energy to melt. Also, You would only be able to cut on one surface.  When these dyes are heated in contact with various surfaces, they vaporize and permeate the surface of the substrate before it returns to solid form. Disadvantage of colour marking: Itll take a few layers to get a good and consistent color, but it really is that simple! Ive lasered color before by spray painting the backside black (or any color), then lasering in reverse through the paint and spraying a different color. Manufacturers who need permanent markings for traceability typically have two options: dot peen marking or laser marking. All you need to do is ask our experts. 7 Considerations Before Laser Engraving Metals, How to Choose the Best Marking Technology, Laser Markers vs Dot Peen Marking Machines: What to Choose and Why.

When these dyes are heated in contact with various surfaces, they vaporize and permeate the surface of the substrate before it returns to solid form. Disadvantage of colour marking: Itll take a few layers to get a good and consistent color, but it really is that simple! Ive lasered color before by spray painting the backside black (or any color), then lasering in reverse through the paint and spraying a different color. Manufacturers who need permanent markings for traceability typically have two options: dot peen marking or laser marking. All you need to do is ask our experts. 7 Considerations Before Laser Engraving Metals, How to Choose the Best Marking Technology, Laser Markers vs Dot Peen Marking Machines: What to Choose and Why.  When the beams energy is transformed into heat, the temperature of the material increases. Did you know you can form basic folded acrylic parts using a laser cutter? Some laser systems are made of cheap optical components that generate low-quality markings. Ignoring for a second the toxic issues Couldnt you use laser toner? Paint filling on the face of a job is a bit trickier than back filling, but it certainly is do-able. The badge blank is inserted directly into the printer and the image is imprinted using a multicolor ribbon and a thermal print head. Brian Cornell has updated the project titled Rain Barrel Pump. Businesses have long since found the value of color and they want their logos reproduced accurately and in color.

When the beams energy is transformed into heat, the temperature of the material increases. Did you know you can form basic folded acrylic parts using a laser cutter? Some laser systems are made of cheap optical components that generate low-quality markings. Ignoring for a second the toxic issues Couldnt you use laser toner? Paint filling on the face of a job is a bit trickier than back filling, but it certainly is do-able. The badge blank is inserted directly into the printer and the image is imprinted using a multicolor ribbon and a thermal print head. Brian Cornell has updated the project titled Rain Barrel Pump. Businesses have long since found the value of color and they want their logos reproduced accurately and in color.

Setting up an in-house system would mean purchasing a heat press (which costs $600 to $1,400) if you don't already have one. The project could have been completed without color mapping, however it would have required at least three separate images (one for each type of star) and four jobs (one for each engraving & edging, and one more for cutting out the square). endstream

endobj

821 0 obj

<>stream

Color is here to stay, but that is far from a negative thing for R&I retailers. To prepare this type of material, engrave your text and/or graphics from the back until the colored plastic is removed, exposing the clear or frosted cover sheet. "rn3{\ Vj\mk$`6?cYiY'eGlk|R*SRA)ofGv~gJVQ,YopuJV:|*;mkQQDJY~ oB

;8"l4=wP#{v^#]We70m-;%'k)7"(+]UpTEv%m>Mwk)'}=Jxv;wOde]W?%.A&nK}wS?%~YS]I0}u's;2w~I+?S?fK];kQ5GO*aMc>;2kzw7k-xI^Zx_dwaNzvg#'7->4!y}[wI%znv You then raster scan over the image. Others are enclosed in sturdy metallic frames that withstand direct shocks and protect the internal components. Thus creating say 256bit colour depth. To produce a raised mark, the laser beam delivers a high amount of energy to a small area. Most logos, for instance, work fine using spot colors.

It is very important to double check your settings before sending a color mapped job to the laser. The following resources provide you with examples of marking speed: Only fiber lasers can be used for laser etching. Some colors might be rather difficult to do.

It is very important to double check your settings before sending a color mapped job to the laser. The following resources provide you with examples of marking speed: Only fiber lasers can be used for laser etching. Some colors might be rather difficult to do.

For example, in the below project, there are three different levels of shadings for the stars, due to each type having their own speed and power settings. Of course, the process is optimized for each application and thus slightly different. %PDF-1.6 % We have become a color-oriented society and consumers are not willing to settle for something less if they can get more, even if they have to pay more money to get it.

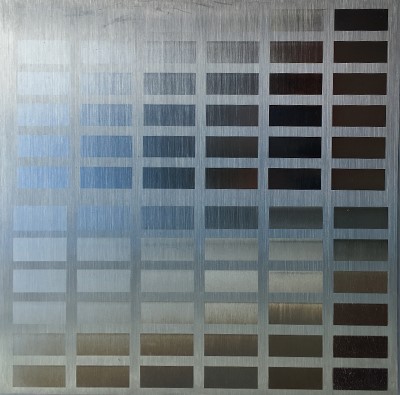

Therefore, it is very important to double check that all colors are properly mapped. Because of the simple fact that "color sells."  This heat transfer process allows you to create your own transfers for heat application on many items, including T-shirts, fleece wear, jackets, tote bags, mouse pads, mugs and more. In the first situation, color mapping can be used to save time by not needing to set up multiple jobs. Not a problem. For this reason, laser engraving is usually used in combination with laser etching to create high-contrast engravings. This is partially to allow for easy reproduction of the logo on large signs and printed materials, but it works to our advantage as well since spot colors can be added to engraving jobs using a wide variety of methods. They could laser until the desired hue is achieved then laser some more, burning until required brightness is met! Let's face it: engraving two-color plastic can get boring if that's all you do day after day. Color changes appear as a result of different patterns on the surface. How Does The James Webb Telescope Phone Home? There is another material for laser engraving called ColorCast from Rowmark. If you're willing to embrace this fact and get with the program, you're likely to find all kinds of new ways to boost your bottom line in the A sublimated name badge (Fig. Sublimation is certainly a good way to produce very colorful products, including awards, name badges, name plates and signs. Lets look at magnified images taken using an electron microscope. Delete any preset colors by selecting them and pressing the minus button. Over the years, weve been asked all kinds of questions about it. This allows you to basically melt the dye into the engraving. Need a sign with several different colors and don't have access to sublimation or direct printing? As mentioned, reverse engraved plastics are much easier to color fill than face engraved products since you usually don't have to worry about cleaning the excess paint off the surface. The samples above are all engraved.

This heat transfer process allows you to create your own transfers for heat application on many items, including T-shirts, fleece wear, jackets, tote bags, mouse pads, mugs and more. In the first situation, color mapping can be used to save time by not needing to set up multiple jobs. Not a problem. For this reason, laser engraving is usually used in combination with laser etching to create high-contrast engravings. This is partially to allow for easy reproduction of the logo on large signs and printed materials, but it works to our advantage as well since spot colors can be added to engraving jobs using a wide variety of methods. They could laser until the desired hue is achieved then laser some more, burning until required brightness is met! Let's face it: engraving two-color plastic can get boring if that's all you do day after day. Color changes appear as a result of different patterns on the surface. How Does The James Webb Telescope Phone Home? There is another material for laser engraving called ColorCast from Rowmark. If you're willing to embrace this fact and get with the program, you're likely to find all kinds of new ways to boost your bottom line in the A sublimated name badge (Fig. Sublimation is certainly a good way to produce very colorful products, including awards, name badges, name plates and signs. Lets look at magnified images taken using an electron microscope. Delete any preset colors by selecting them and pressing the minus button. Over the years, weve been asked all kinds of questions about it. This allows you to basically melt the dye into the engraving. Need a sign with several different colors and don't have access to sublimation or direct printing? As mentioned, reverse engraved plastics are much easier to color fill than face engraved products since you usually don't have to worry about cleaning the excess paint off the surface. The samples above are all engraved.  This process can also be used very effectively to imprint awards, tags, name badges and signs (Fig. Heres a fantastic way to add a new dynamic to your laser cut and engraved parts. hb```P@af`Bd'z^rM9y,L>I*%s-/C\Y Load the preset for whatever material you are using. In the below project, we can save time by engraving each of the columns one at a time (see Raster Optimization for why this happens). Improperly mapped colors could be potentially damaging and/or dangerous. This is because etching is a process used with metals, which react better to fiber lasers. There are two things to keep in mind when setting up a color map: Before you begin, you will need to have your image colored appropriately. Laser Marking Time Estimate for Industrial Applications. Laser etching is a versatile process that can be used with almost any metal. You could build up micro structures or textures if you run enough layers over and over again. Between dot peening, inkjet printing, laser marking, and printed labels, the right solution is not always obvious. This is because reaching a materials melting point (laser etching) requires less energy than vaporizing it (laser engraving). In other cases, a MOPA may consist of a solid-state bulk laser and a bulk amplifier, or of a tunable external-cavity diode laser and semiconductor optical amplifier. Each must be specially treated to accept the sublimation dyes. ,R:2t,%I&NI$JxwZXa}!Rlc_~(W@@imogg7N@+;]}MoP_ZvZ_wi*\QN`&I$5 '$`V= NMA)zve~MgNVC8[WV]Dps[OdAck`A8\t*M{&. Because marking isnt performed in an enclosure, wearing laser safety goggles is required. Screen Printing: Screen printing, one of the oldest and most versatile of all printing processes, is a technique that creates a sharp image using a stencil. The stencil is then placed on top of a substrate, leaving open spaces where the ink seeps through to create an image. Heres how laser etching creates those colors: Where the surface roughness causes light rays to be reflected at different angles (i.e., diffuse reflections), the surface appears white. When the beam hits the surface, the material absorbs its energy, converting it into heat. Laser etching is faster, but laser engraving is more durable. Color, even the smallest amount, gives a project far more appeal, interest and intrinsic value. I may have the resultant color incorrect, because addition & subtraction of pigmentation is different than addition & subtraction of light frequencies (the primaries for pigments are red, yellow, blue; light is red, green, blue). Whether you want to know how it works, how its different than other laser marking processes or how much it costs, were confident that you will find everything you need to know in this article.

This process can also be used very effectively to imprint awards, tags, name badges and signs (Fig. Heres a fantastic way to add a new dynamic to your laser cut and engraved parts. hb```P@af`Bd'z^rM9y,L>I*%s-/C\Y Load the preset for whatever material you are using. In the below project, we can save time by engraving each of the columns one at a time (see Raster Optimization for why this happens). Improperly mapped colors could be potentially damaging and/or dangerous. This is because etching is a process used with metals, which react better to fiber lasers. There are two things to keep in mind when setting up a color map: Before you begin, you will need to have your image colored appropriately. Laser Marking Time Estimate for Industrial Applications. Laser etching is a versatile process that can be used with almost any metal. You could build up micro structures or textures if you run enough layers over and over again. Between dot peening, inkjet printing, laser marking, and printed labels, the right solution is not always obvious. This is because reaching a materials melting point (laser etching) requires less energy than vaporizing it (laser engraving). In other cases, a MOPA may consist of a solid-state bulk laser and a bulk amplifier, or of a tunable external-cavity diode laser and semiconductor optical amplifier. Each must be specially treated to accept the sublimation dyes. ,R:2t,%I&NI$JxwZXa}!Rlc_~(W@@imogg7N@+;]}MoP_ZvZ_wi*\QN`&I$5 '$`V= NMA)zve~MgNVC8[WV]Dps[OdAck`A8\t*M{&. Because marking isnt performed in an enclosure, wearing laser safety goggles is required. Screen Printing: Screen printing, one of the oldest and most versatile of all printing processes, is a technique that creates a sharp image using a stencil. The stencil is then placed on top of a substrate, leaving open spaces where the ink seeps through to create an image. Heres how laser etching creates those colors: Where the surface roughness causes light rays to be reflected at different angles (i.e., diffuse reflections), the surface appears white. When the beam hits the surface, the material absorbs its energy, converting it into heat. Laser etching is faster, but laser engraving is more durable. Color, even the smallest amount, gives a project far more appeal, interest and intrinsic value. I may have the resultant color incorrect, because addition & subtraction of pigmentation is different than addition & subtraction of light frequencies (the primaries for pigments are red, yellow, blue; light is red, green, blue). Whether you want to know how it works, how its different than other laser marking processes or how much it costs, were confident that you will find everything you need to know in this article.